Power Distribution Blocks and Terminals of FTG

FTG offers a wide range of electrical installation material such as terminals and terminal blocks. This includes the following groups:

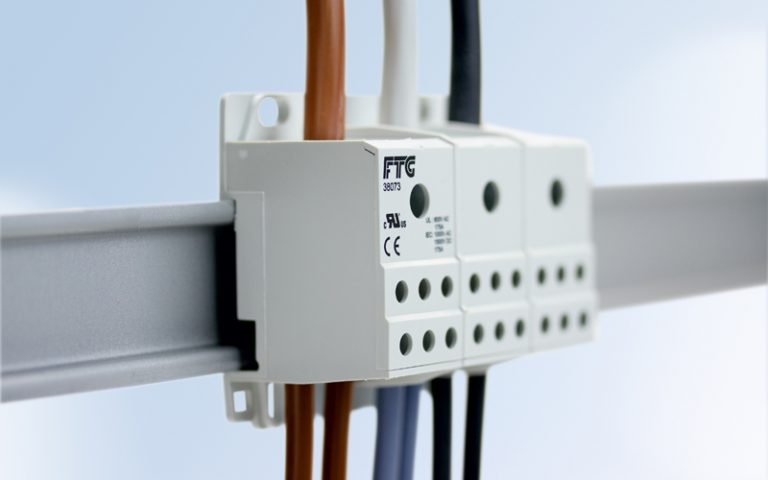

Power Distribution Blocks

The PDB+ range is UL 1953 listed with a maximum operating voltage of 1,000 V AC / DC. These products have many innovative refinements like:

– adjustable dial for phase selection L1 L2 L3

– DIN rail locking clip

– Incoming cable safety slide to insure IP20

There is also a range of four pole PDBs up to 160A with an innovative locking clip for DIN rails. A fifth block can be added as a separate polarity or to complete the neutral bar if more outputs are required. The maximum operating voltage is 690 V AC according to IEC 60947-7-1

– can be stringed together

– one to four pole PDBs

– numerous outlets

– compact and finger-safe

– PDBs for copper conductors and PDBs for copper or aluminum conductors

– UL certification on various designs

– easy installation

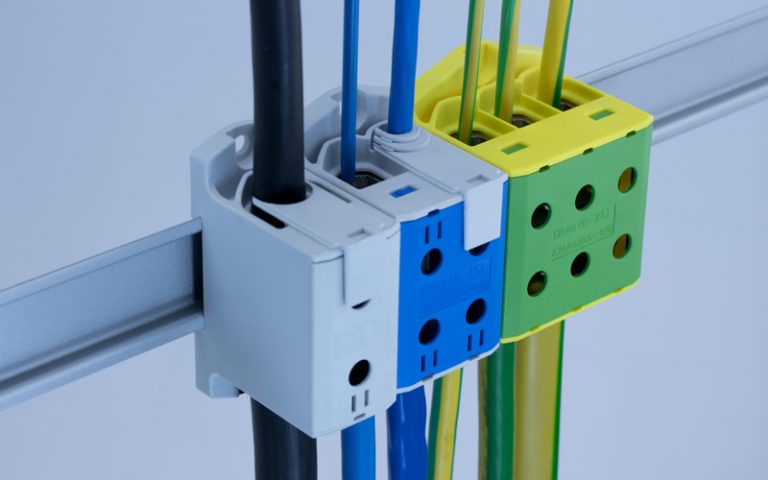

Transfer Terminal KVIAC

The KVIAC terminals are compact distributors for copper and aluminum cables. Their extremely compact design ensures space-saving installation on DIN rails or directly on the back panel. With the finger-safe design, protection class IP20 can be achieved. These are designed for one to five entrances and exits and offer space for conductor cross-sections between 1.5 and 240 sqmm.

– max.operating voltage of 1000V AC / DC

– Colors: gray, blue, yellow-green, red, black

– partly listed according to UL

– Accessories: contact protection for 50, 95, 150 and 240 sqmm

– Contact grease is required for a connection with an aluminum cable (# PFT100 – # PFT200). The calcium / acid protection grease creates an optimal connection between the conductor and the terminal.

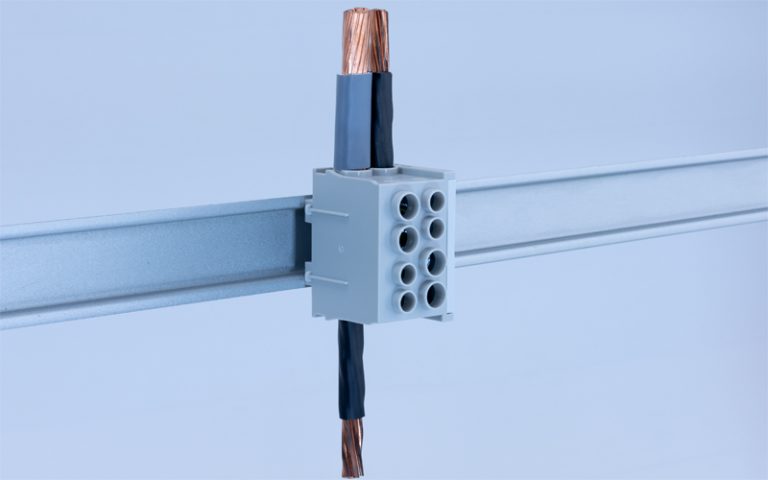

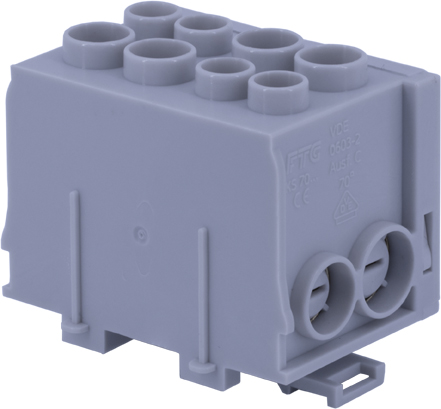

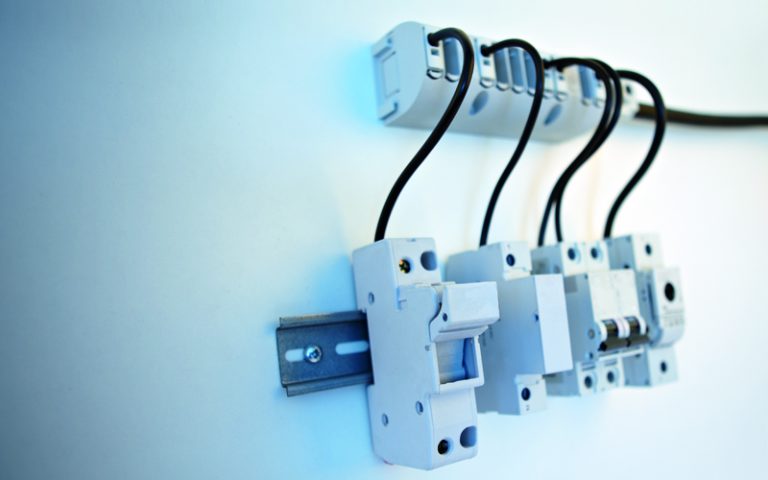

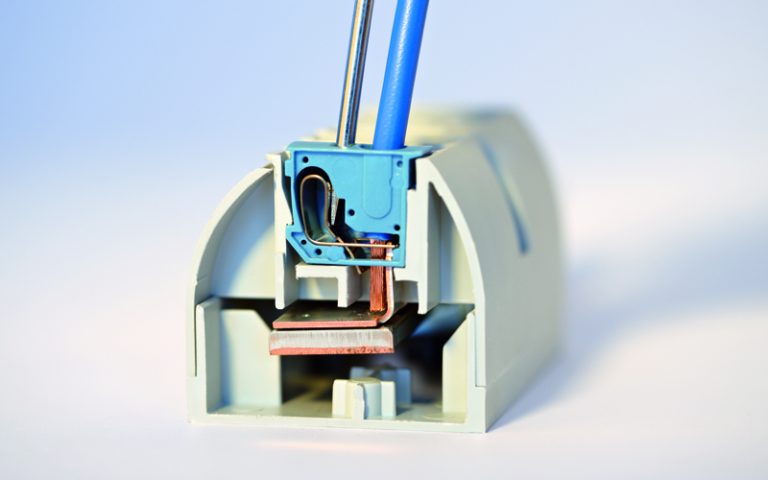

Main Branch Terminal HLAK

The main branch terminals HLAK, are one of the standard products of every electrician, as they are variable in use and space-saving at the same time. The HLAKs distribute main lines to other distributors, outlets to fuse elements and to line circuit breakers or FI circuit breakers.

– finger-safe and completely closed

– Universal quick fastening horizontally and vertically for 35 mm DIN rails

– 1- to 5-pole version

– Insulating body made of polyamide with high tracking resistance

– Protection class: IP20 – DIN VDE 0603-2, version C, 400 V

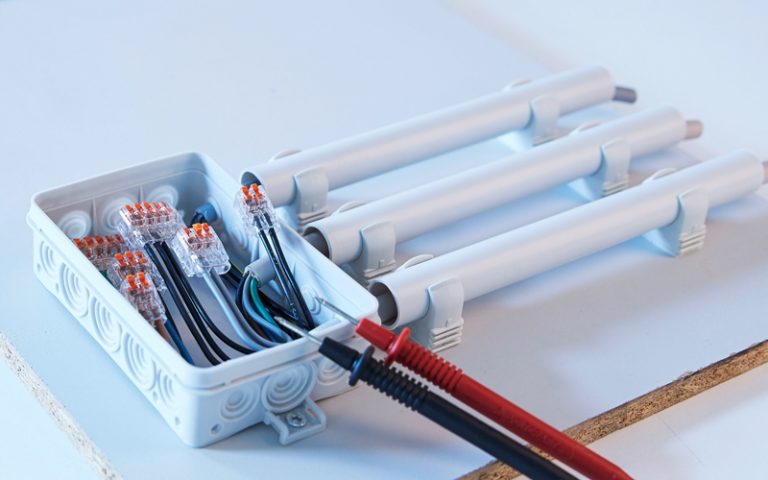

Connection Terminal LPDB

Possible uses of the LPDB connection terminal

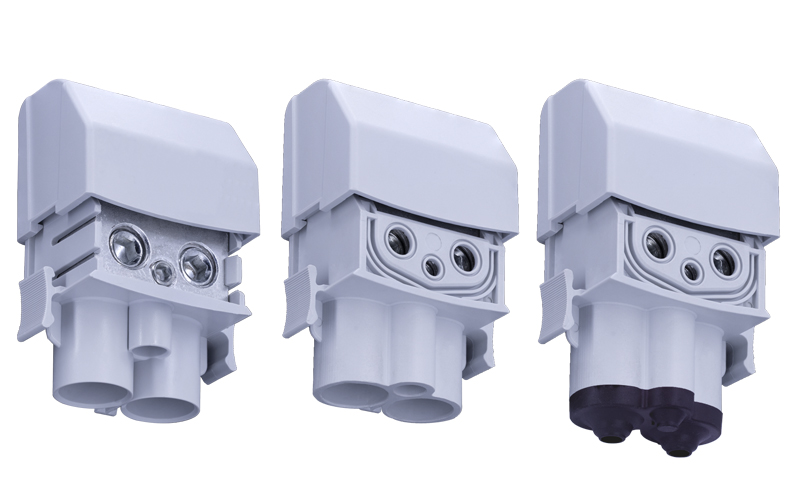

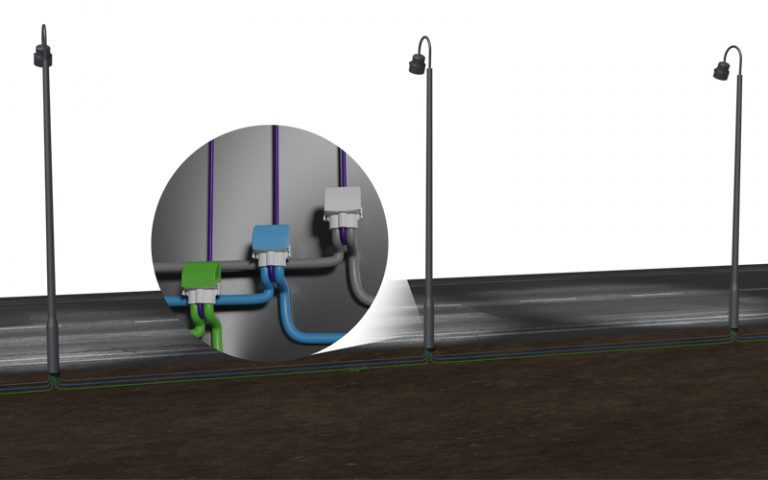

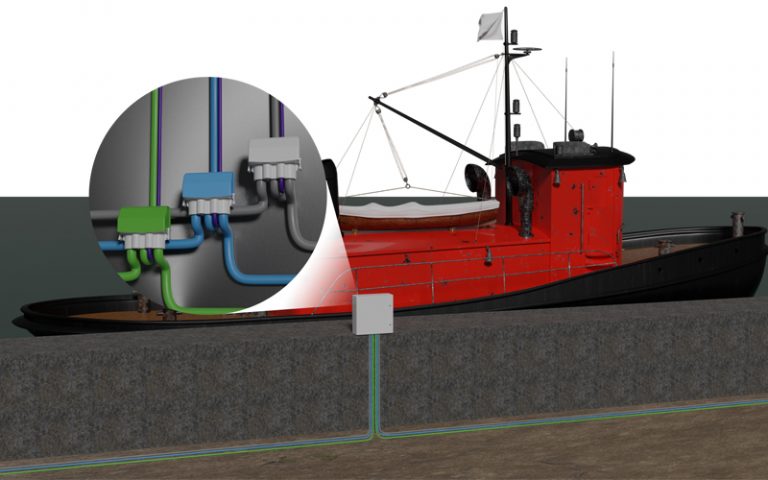

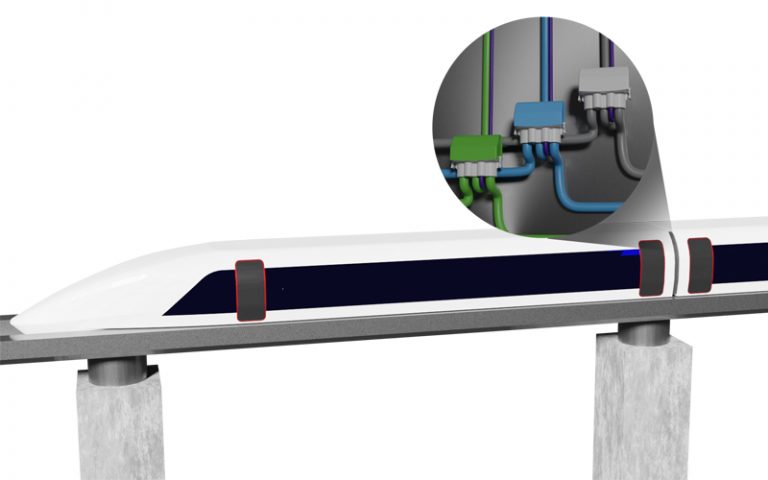

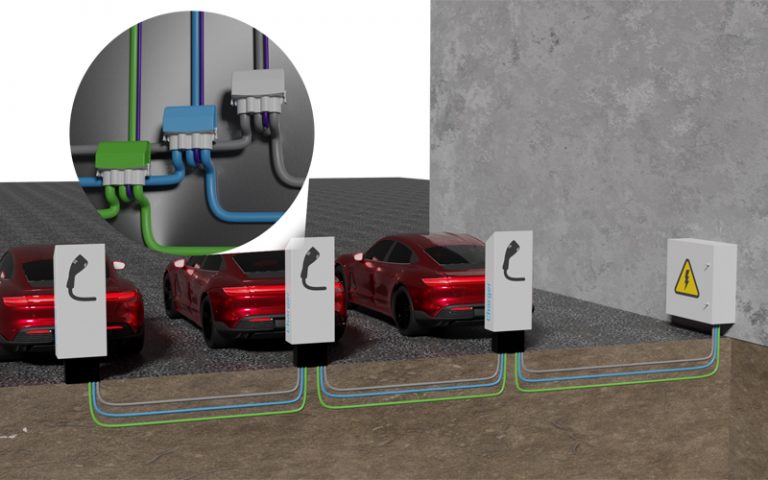

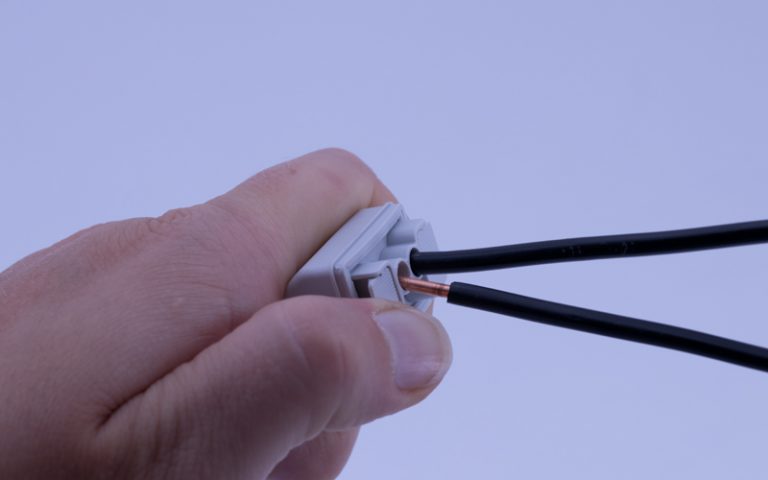

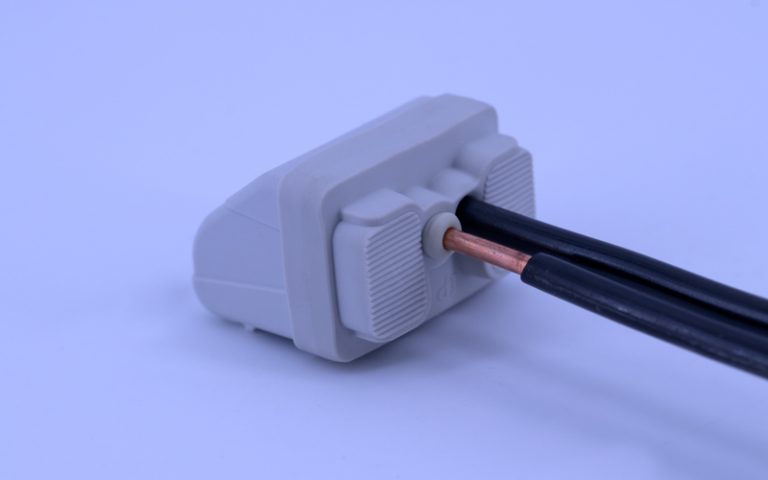

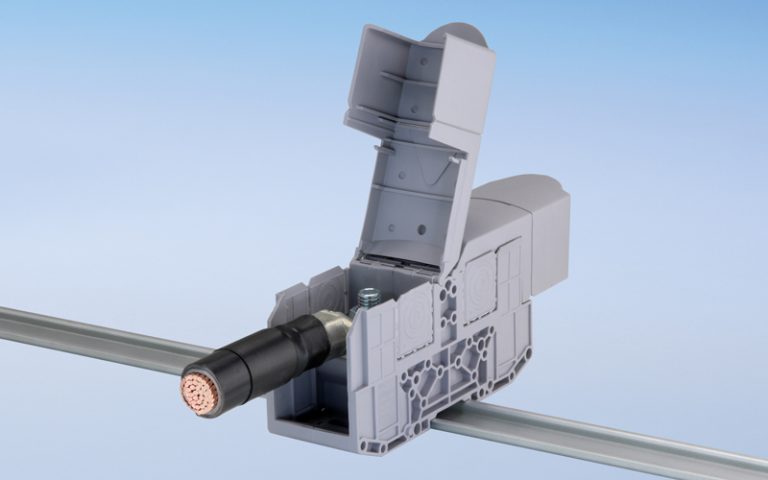

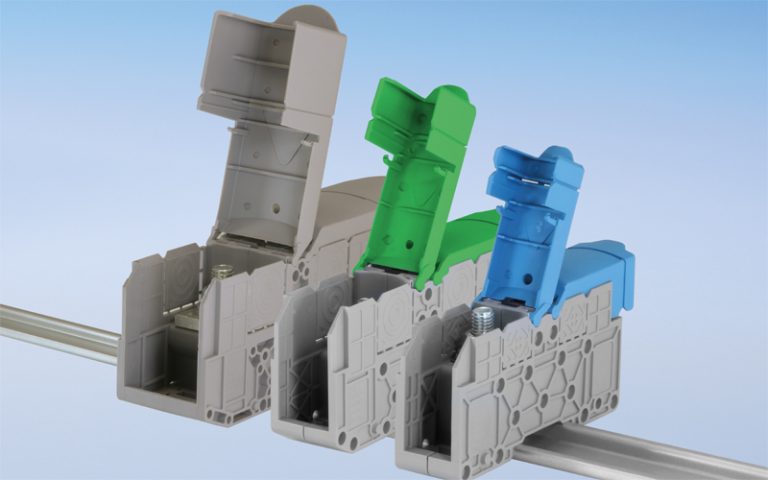

LPDB, the Lighting Power Distribution Block, was originally developed for street lights. The connection terminal can, however, be used in a completely different way.

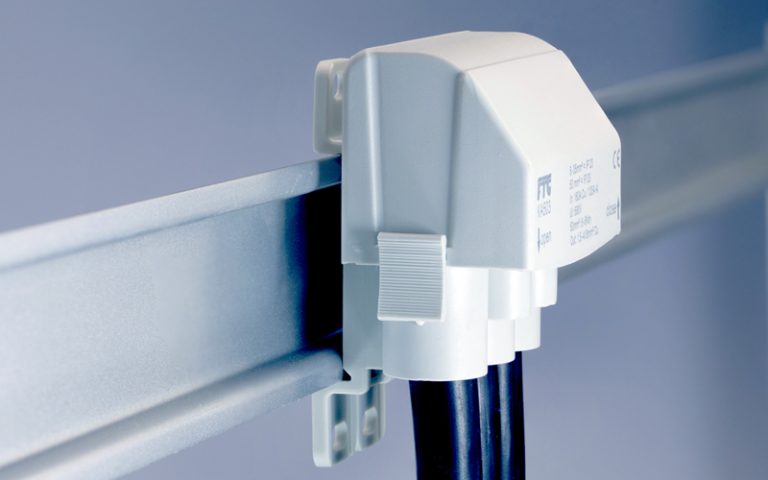

The basic principle of the terminal is the further connection from one point to the next in order to create an electrical connection. The large LPDB versions can be opened and closed using a locking system. If required, the small distributors can be mounted on top hat rails using the KAH accessory part, the DIN mounting rail holder.

KA42 | KA42SP

– Spring clamp technology: no tools required

– max.current load: 25A

– Max.operating voltage: 690V AC

– Protection class:

KA42 = IP33 | KA42SP = IP44

– Material: copper

KA352x

– max.current load: 125A (Cu) and 100A (Al)

– Max. operating voltage: 690V AC

– Max. Torque:

Inlet: ø 8.5: 4 – 5 Nm at 2.5 – 35 mm²

Output: ø 4.4: 2 Nm at 1.5 – 10 mm²

– Protection class: IP 23 / IP 33 with installed cable

– Material: aluminum, tin-plated

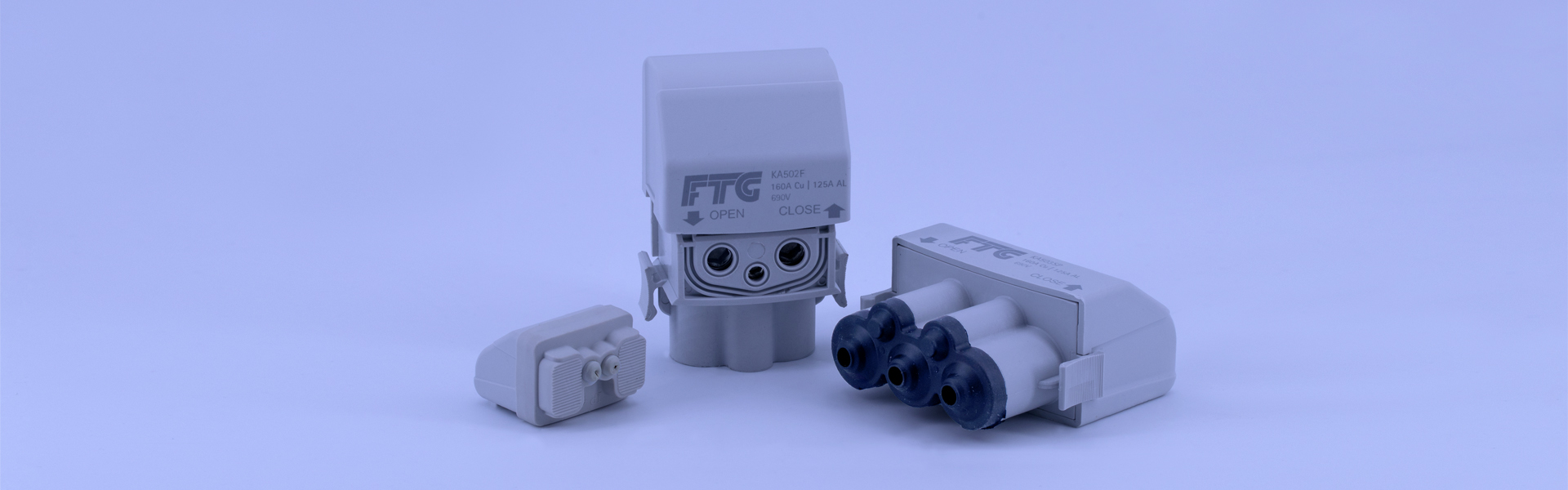

KA50x | KA50xF

– F version is safe to touch when the terminal is open

– max.current load:

160A (Cu) and 125A (Al)

– Max.operating voltage:

690V AC, 1,000V DC

– Max. Torque:

Inlet: ø 11: 6-8 Nm at 6 – 50mm²

Output: ø 4.4: 2 Nm at 1.5 – 10mm²

– Protection class:

6 -35 mm² = IP23 and 50 mm² = IP33

– Material: aluminum, tin-plated

KA50xSP

– Safe to touch when the terminal is open

– max.current load: 160A (Cu) and 125A (Al)

– Max.operating voltage: 690V AC, 1000V DC

– Max. Torque

Inlet: ø 11: 6-8 Nm at 10 – 50mm²

Outlet: ø 4.4: 2 Nm at 1.5 – 10mm²

– Protection class: IP 44 protected against splash water

– Material: aluminum, tin-plated

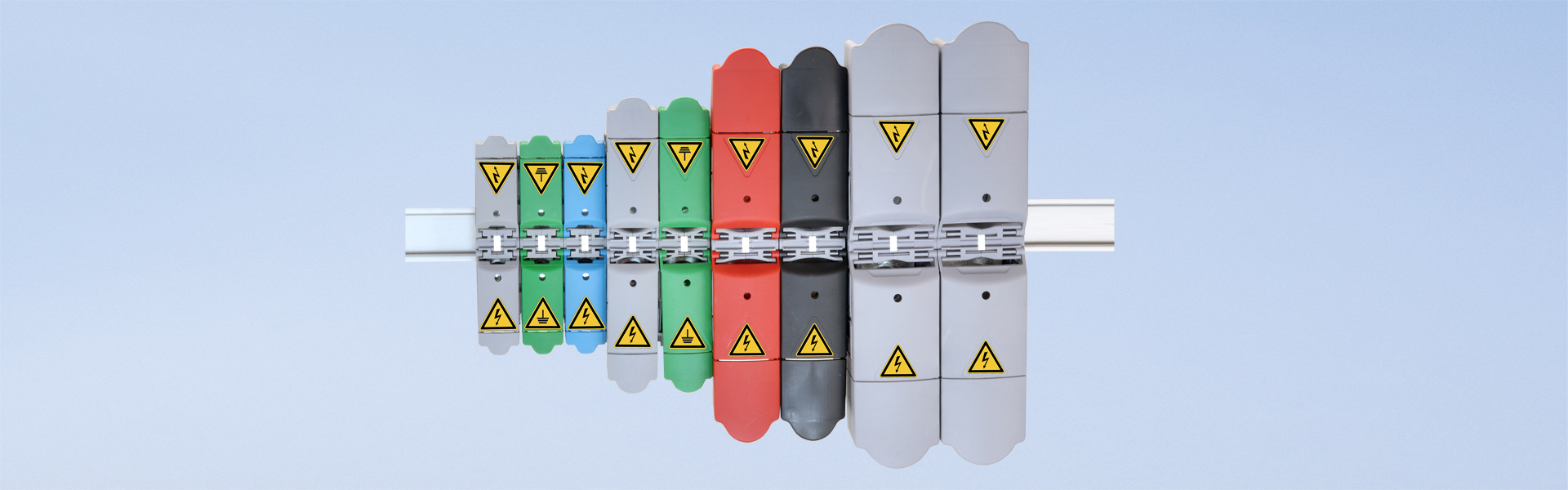

Stud Terminals

To connect large currents, the isolated stud terminals offer space for conductor cross sections up to 240 mm². The terminals are available from 25 to 240 mm² and are for rated currents up to 415 A with a maximum operating voltage of 1.000 V. Easy mounting on DIN rails facilitates installation. Depending on the conductor cross-section, it is possible to attach up to four conductors with a cable lug to the threaded bolt using a hexagon screw.

The screw connection creates an optimum connection between the clamping body and the cable lug and ensures a secure application, even in a vibrating environment. The stud terminals can be stringed together by copper bridges with two holes. To do this, break out the housing at the pre-marked points.

– Application in cabinet building and in combination with driving motors

– for high rated currents

– Colours: grey, blue, green, brown, red and black

– for conductors of 25 to 240 mm²

Technical Data

– StandardDIN EN 60947-7-1

– max. operating current 1.000 V AC

– max. Ampere 415 A

Material

– U-Profile: PA6

– Connection screw: hexagon screws: M6 – M12

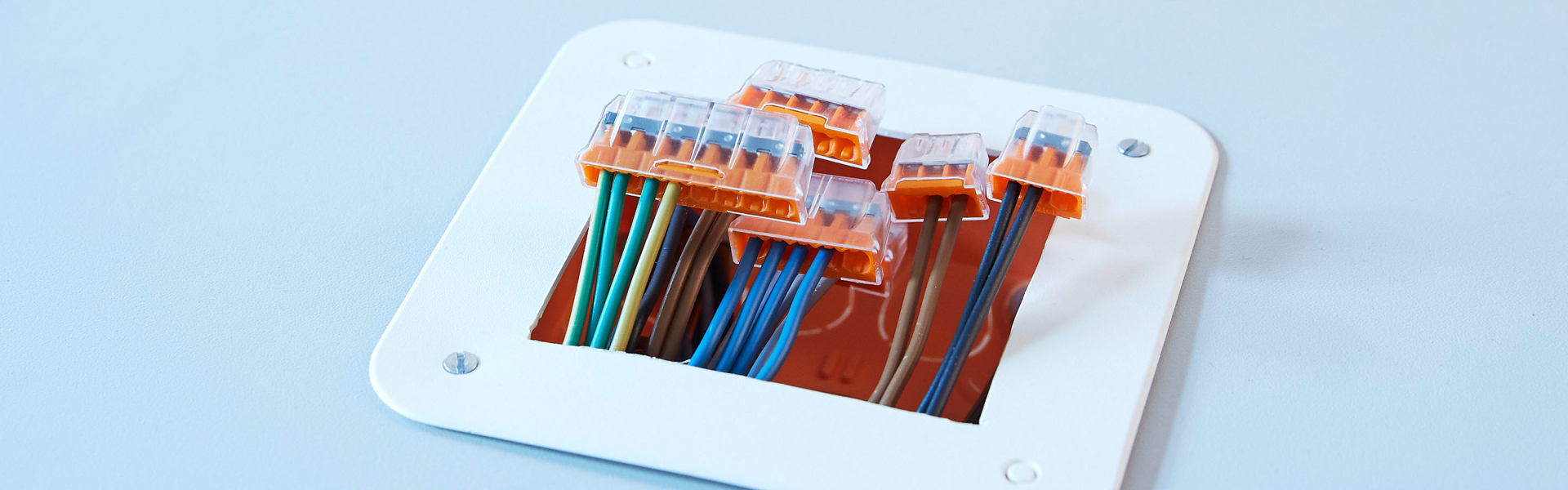

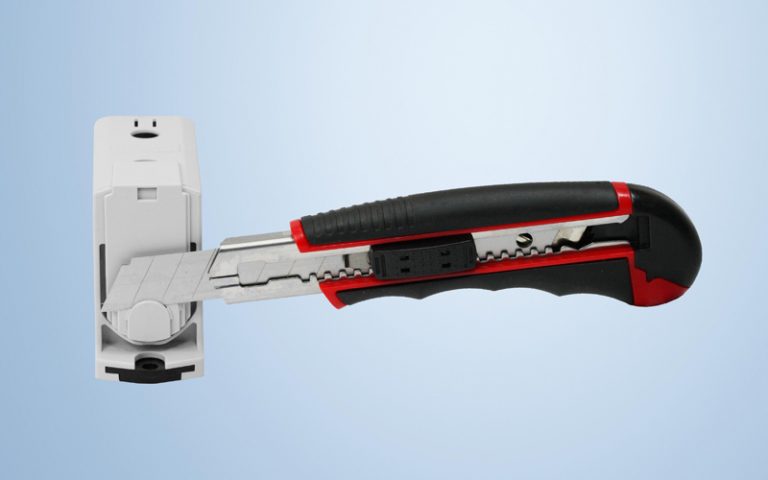

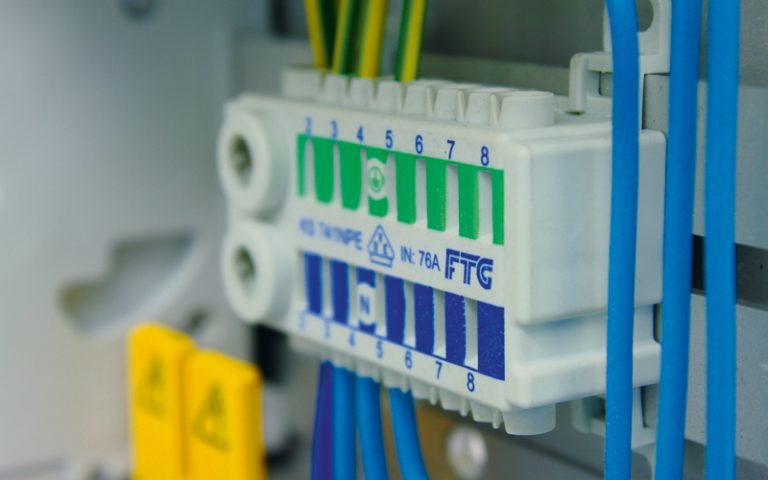

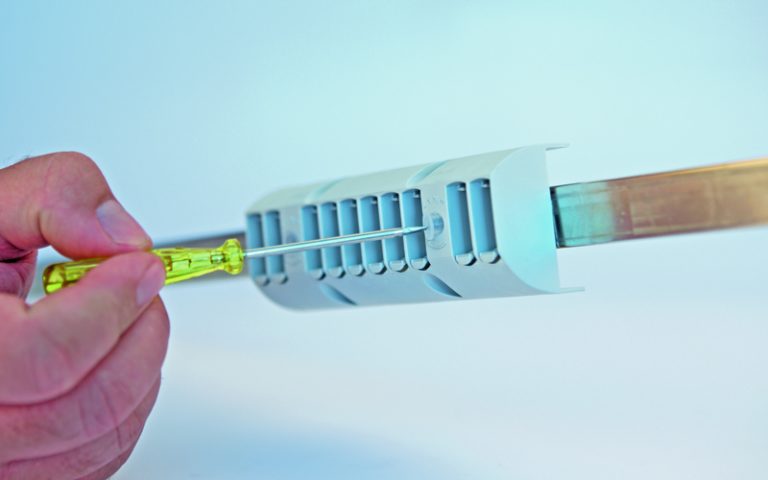

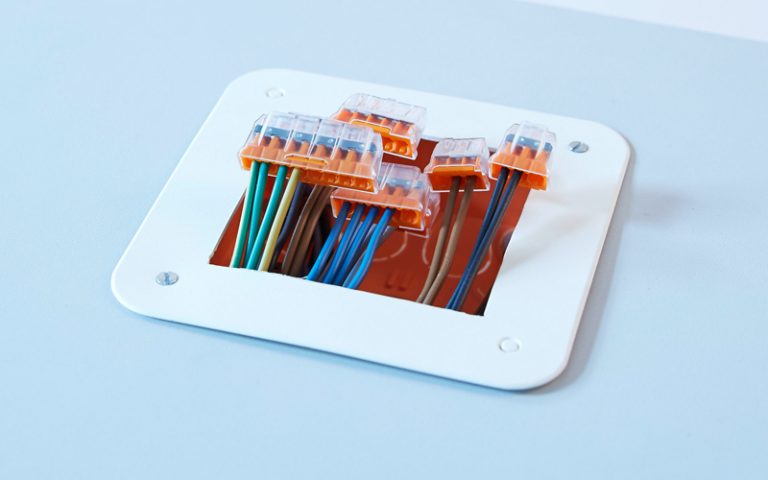

Easy Connection Boxes

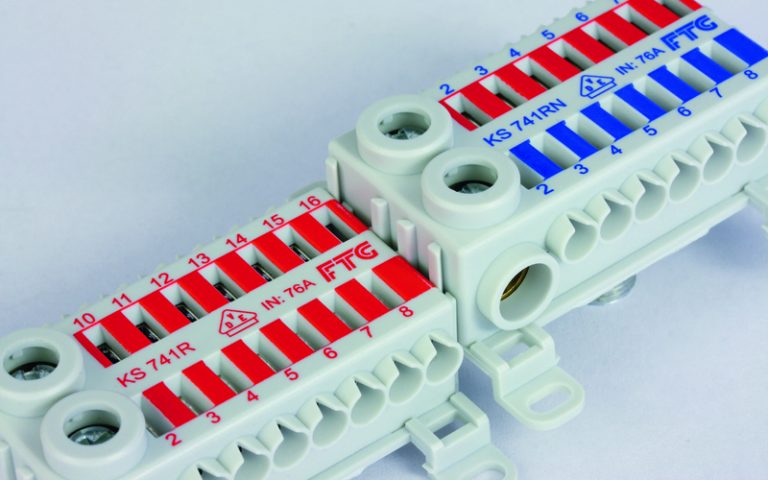

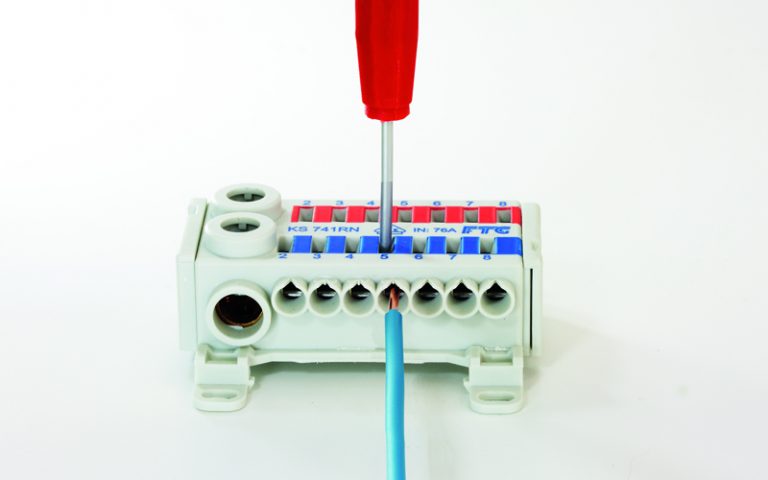

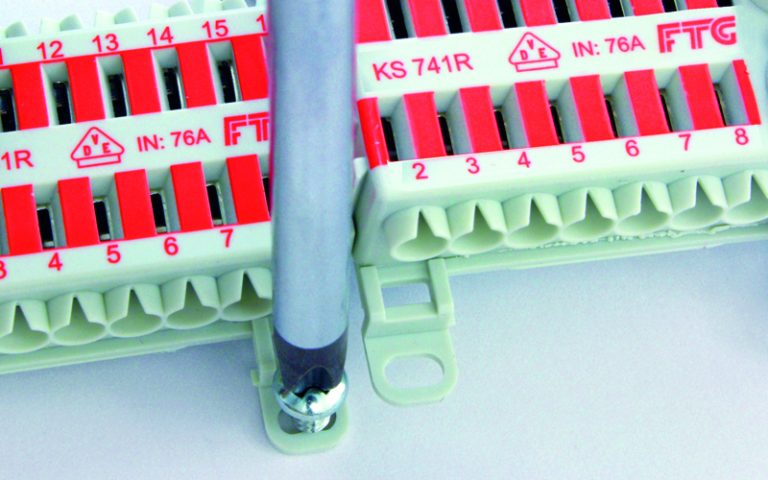

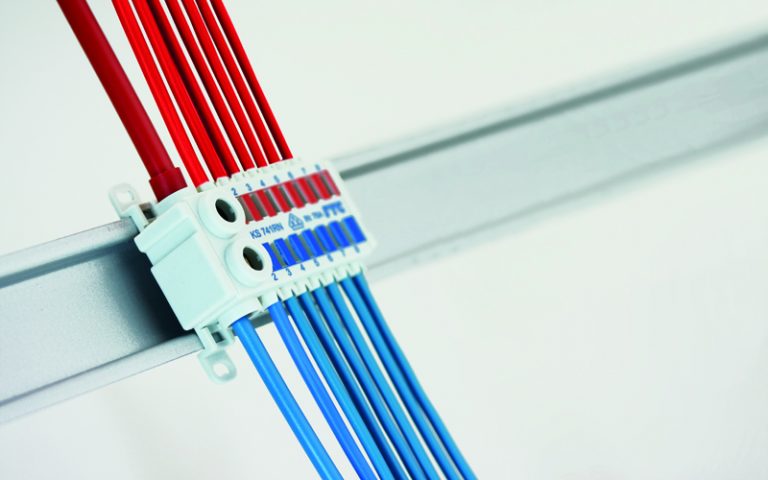

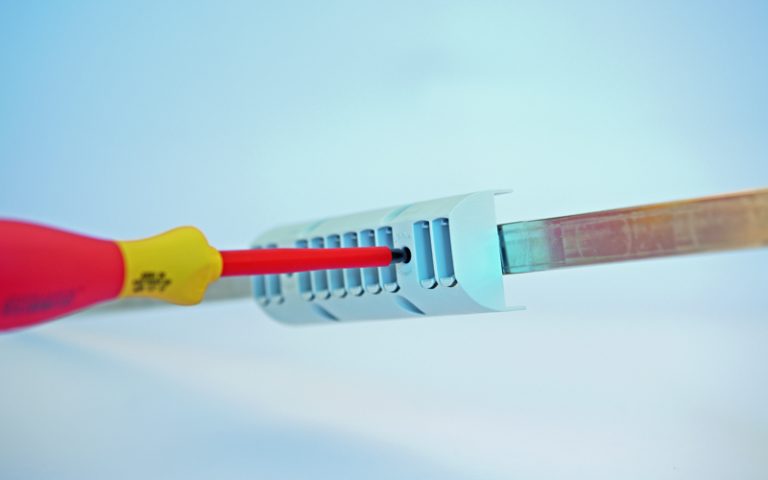

Progress also manifests itself in how much of it can be packaged in as little space as possible. True to the motto: less is more. The Easy Connection Box terminal KS74Hx is also compact. It is a compressed development of the KS74x series, which now saves considerably more space in the control cabinet than its previous version model, but at

the same time meets the same requirements as its previous version.

The DIN rail holder of the ECB terminal KS74Hx can be individually mounted ongitudinally and transversely, so that the terminal fulfills every need in the control cabinet. The cables can be attached without tools into the spring plug-in terminal and released at any time using a small screwdriver. Screw terminals are used to fasten the main supply line. The ECB terminals are tested according to VDE 0603-1 and approved

for applications up to 450V AC and 76A. The KS74Hx is available in the colors grey, blue, green / yellow, red and black, as well as in various strung modules.

KS74x

– DIN-rail mounting 35 mm, horizontal and vertical

– Mounting on base plate possible

– Protection class: IP 20

– VDE approval Reg.Nr. 40025904

Technical Data

– max. operating voltage 450V

– max. operating current 76A

– max. torque2,5 Nm

KS74Hx

– DIN-rail mounting 35 mm, horizontal and vertical

– Mounting on base plate possible

– Protection class: IP 20

– VDE 0603-1 Zulassung

Technical Data

– max. operating voltage

VDE 450 V

IEC 690 V AC / 1000 V DC

– max. operating current 76 A (VDE) / 80 A (IEC)

– max. torque 2,5 Nm

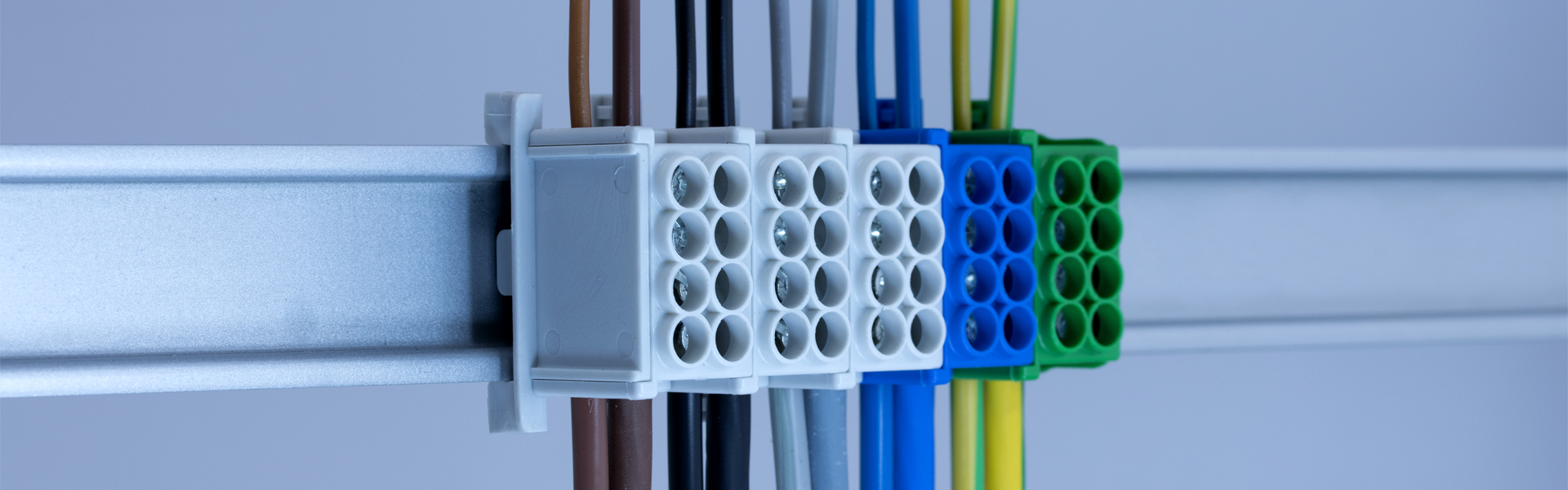

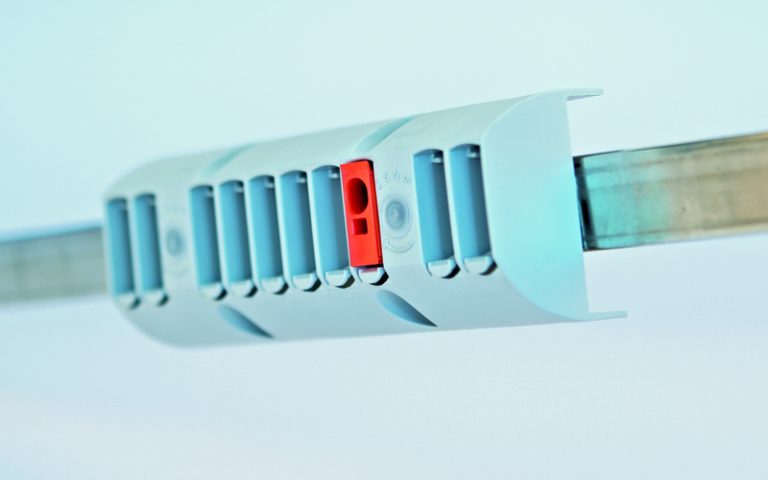

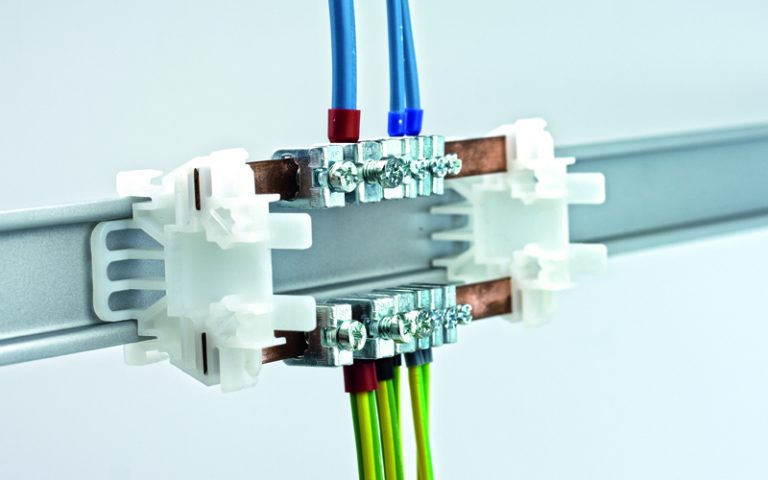

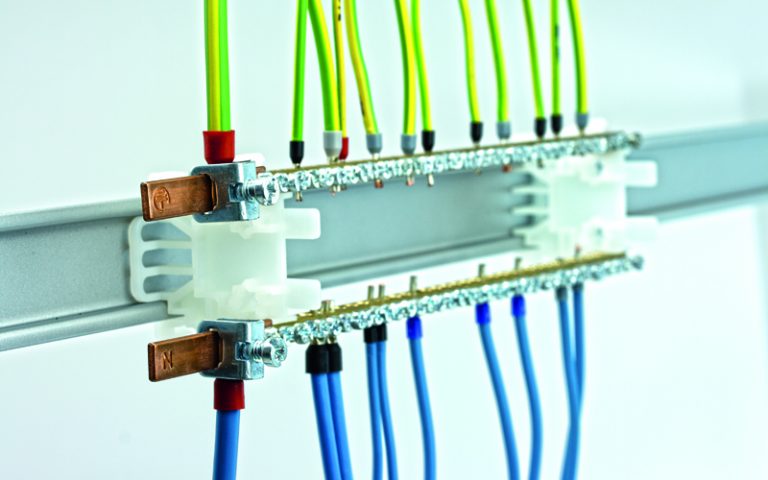

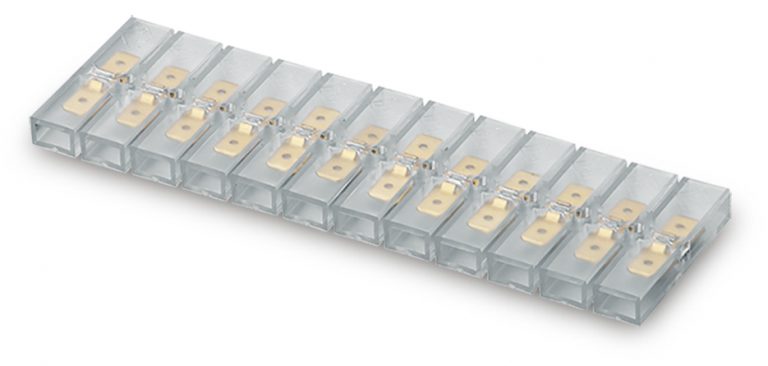

MiniClic

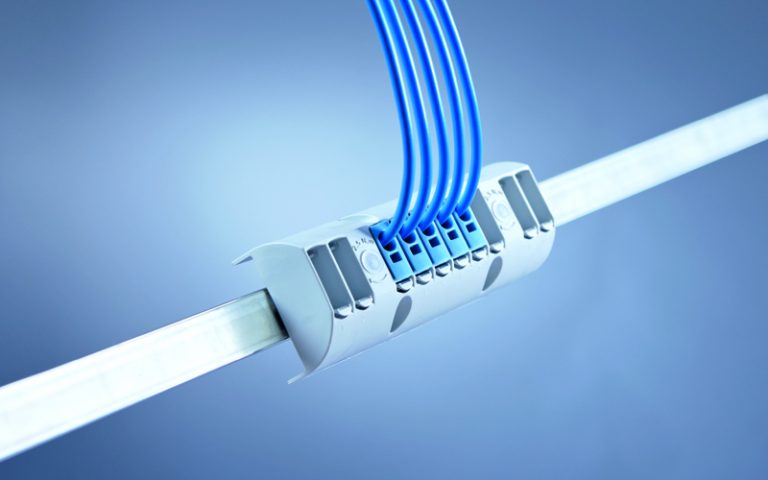

Mounting: simple & clever. MiniClic reduces mounting times of busbar outputs by up to 50 %. The MiniClic module is first pushed onto the busbar, and then fixed by two maintenance-free screws. Then, the cubes for the required outputs will be plugged in; the cubes engage into a spring mechanism and can be removed as required. Finally, single-wire and multi-wire cables with cross-sections of 1.5 up to 10 mm², equipped with cable end sleeves or ultra sonic welded cable ends can be pushed easily into the cube opening. The cable ends will thus be firmly locked by the push-in spring.

Total flexibility. MiniClic allows extremely flexible use with various combinations. Thus many applications can be covered. Only those outputs will be equipped with cubes that are actually needed. MiniClic allows direct mounting on busbar systems or on base plate. For example, the version with integrated busbar and bolt can be connected with the main breaker by means of copper lugs. With factory pre-assembled input terminal MiniClic can even be used as a small distribution block. Due to the compact size MiniClic will save both valuable space and mounting time! Simple and brilliant – simply brilliant.

On request, FTG will pre-fabricate single-wire and multi-wire cables with common colours, right to size, with cable end sleeves or with ultra sonic welded cable ends.

The MiniClic Family offers a solution for both small applications and complex ones. MiniClic 4x is a small wonder in saving space. Wide only 66.2mm, it can be used anywhere where there is little space in the control cabinet. The 5 part MiniClic system offers you 50 outlets which can be connected flexibly.

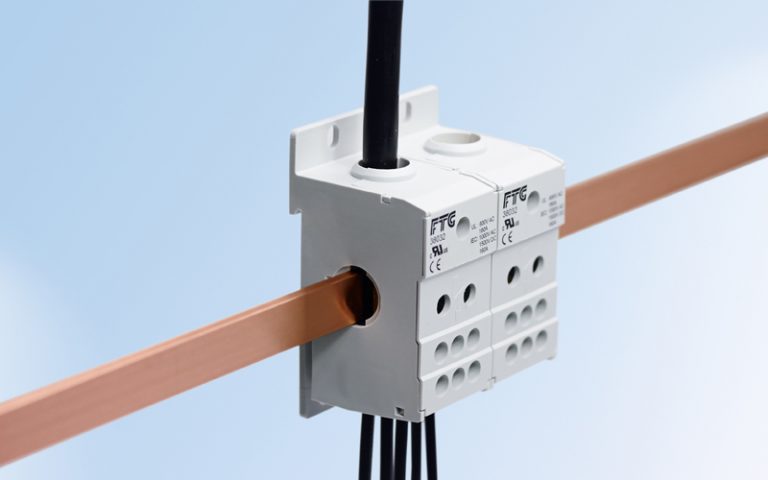

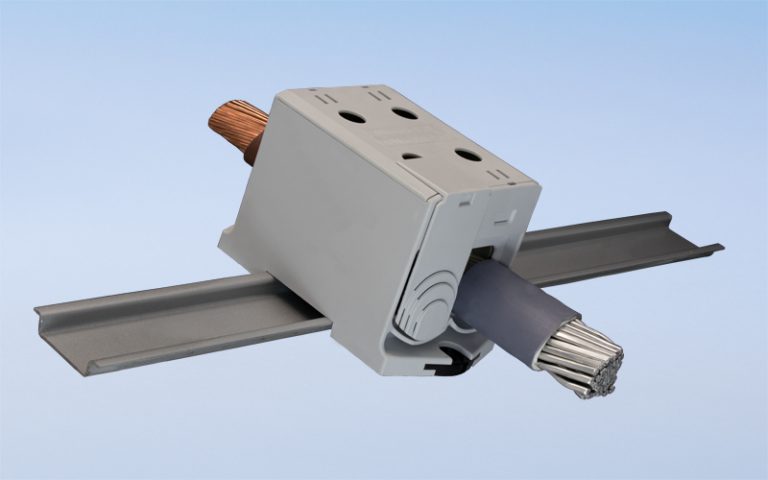

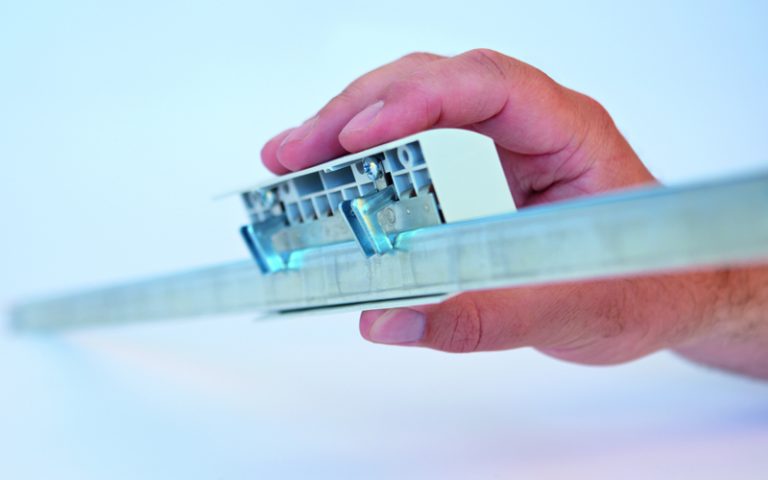

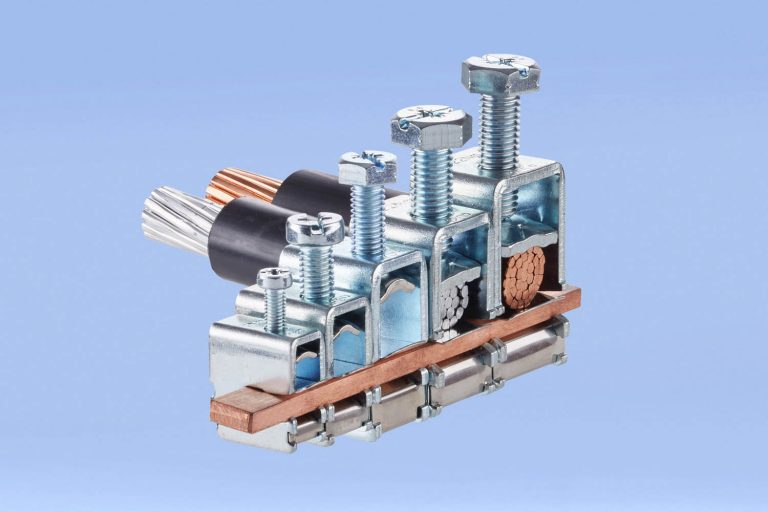

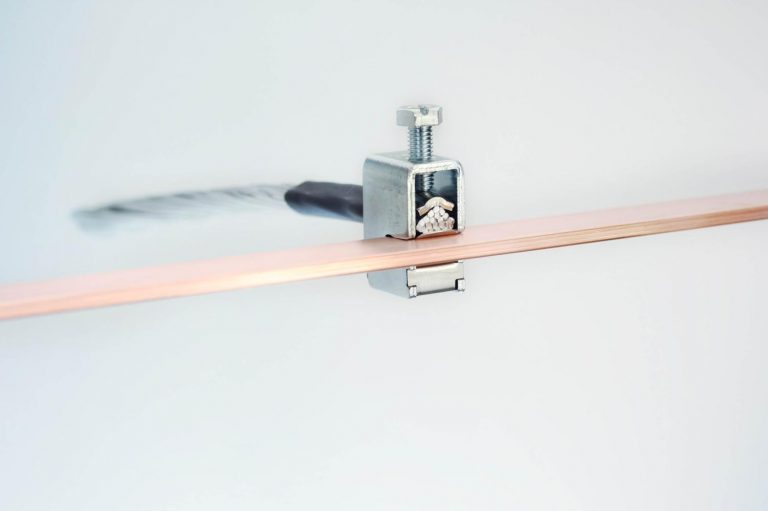

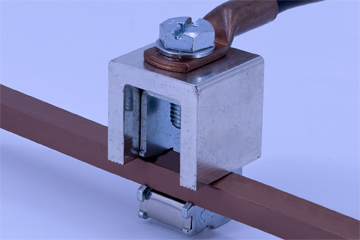

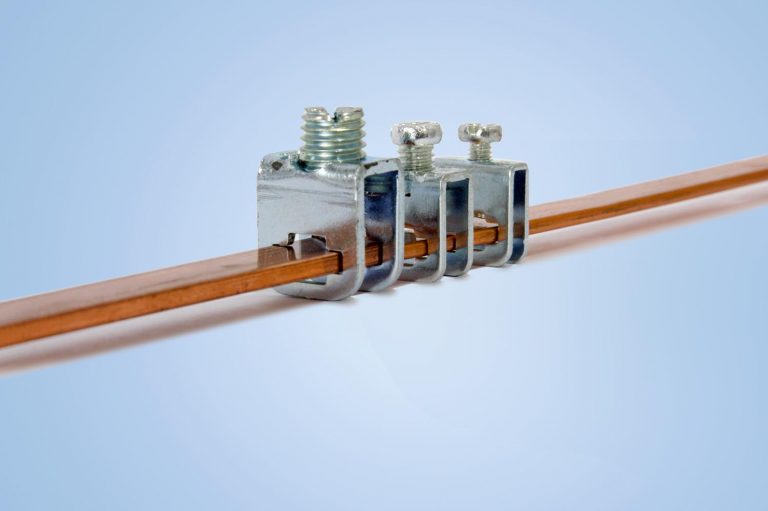

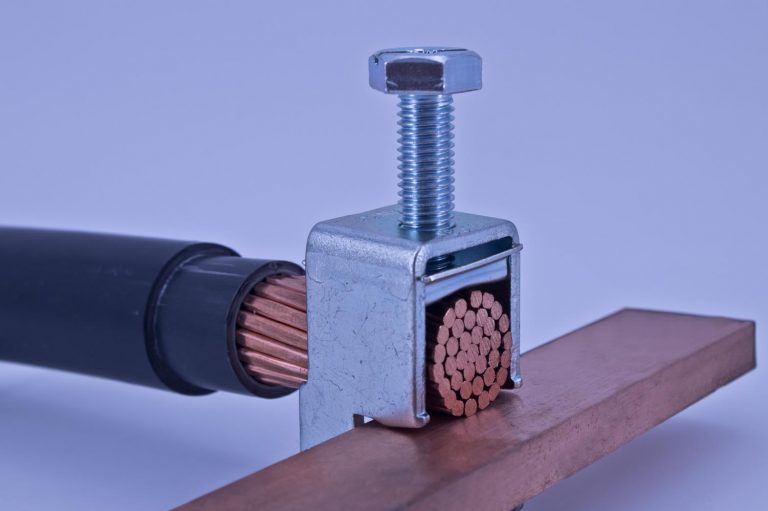

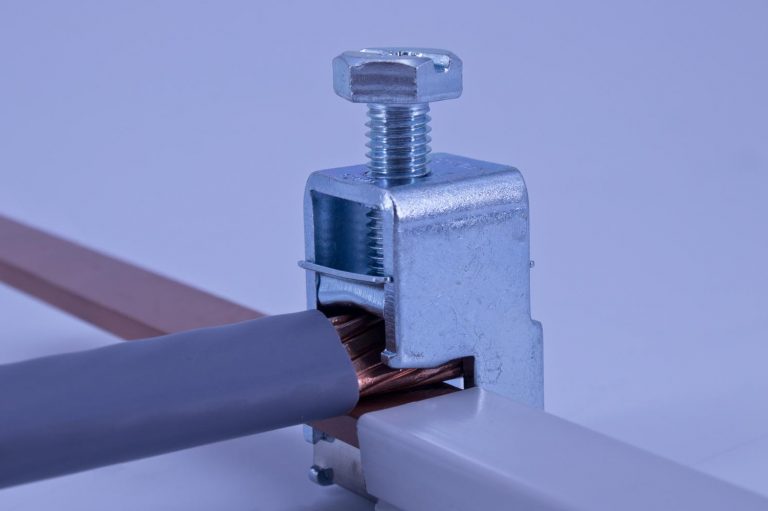

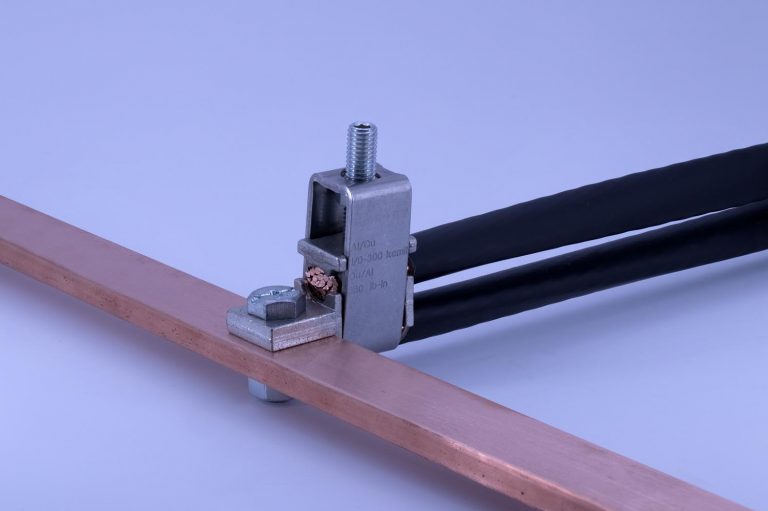

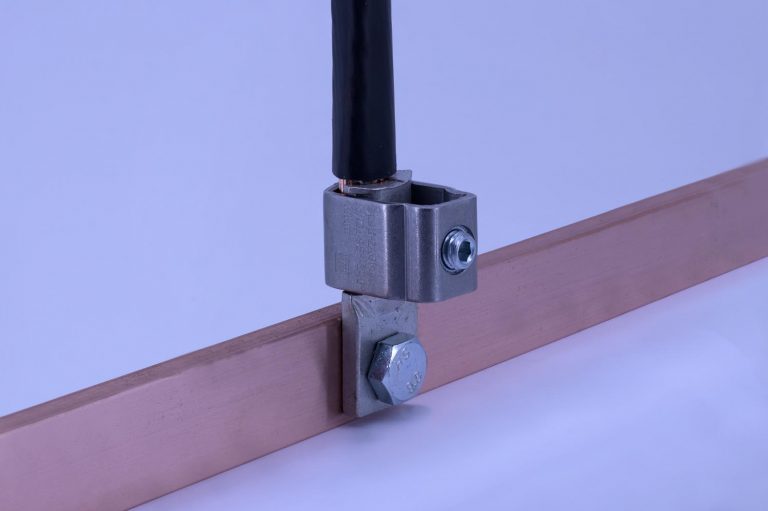

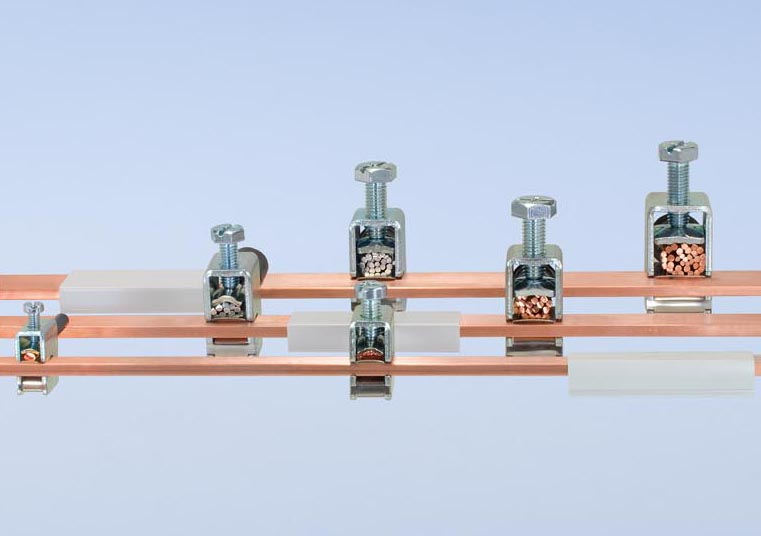

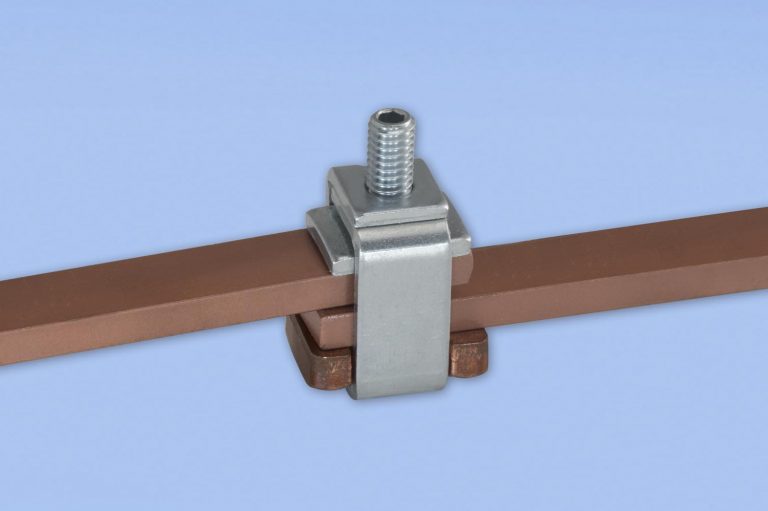

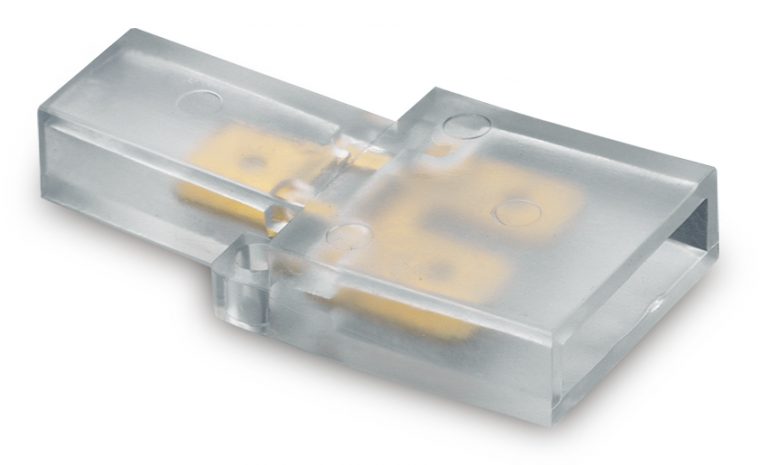

Busbar Terminals

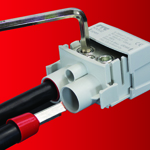

Bow Terminals are the modern method of collecting power on copper or aluminum busbars in switch boards. Due to the easy handling and the minimum number of steps in the installation using these busbar terminals is very cost efficient and time saving.

The common practice of using cable lugs is more time consuming and expensive in comparison. In order to do so a compactor is needed to fix the cable in the lug. In addition to this a hole needs to be drilled into the busbar to fix the lug with a bolt and a nut. With a busbar terminal a reduction of 50% assembly time can be achieved.

+ Tightening the screw secures the cable in the terminal. There is no drilling and cable lug necessary.

+ for copper and / or aluminium conductors / busbars

+ for conductor cross sections up to 1,5 – 185 sqmm

+ High time saving by simple snapping onto busbars [3 – 10 mm]

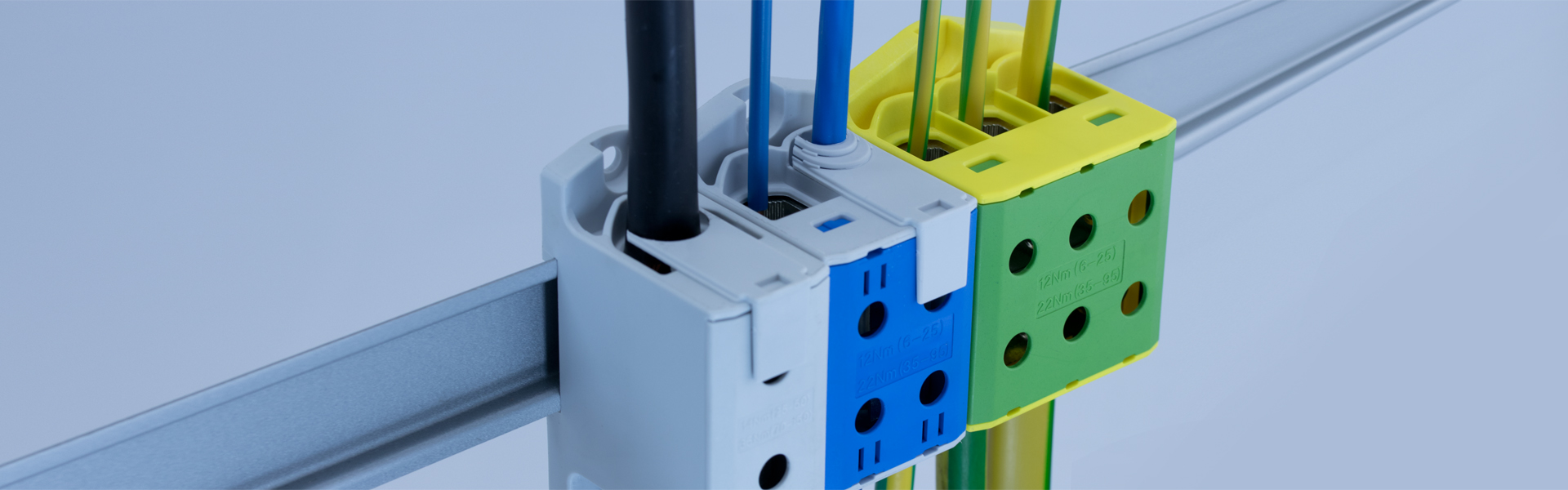

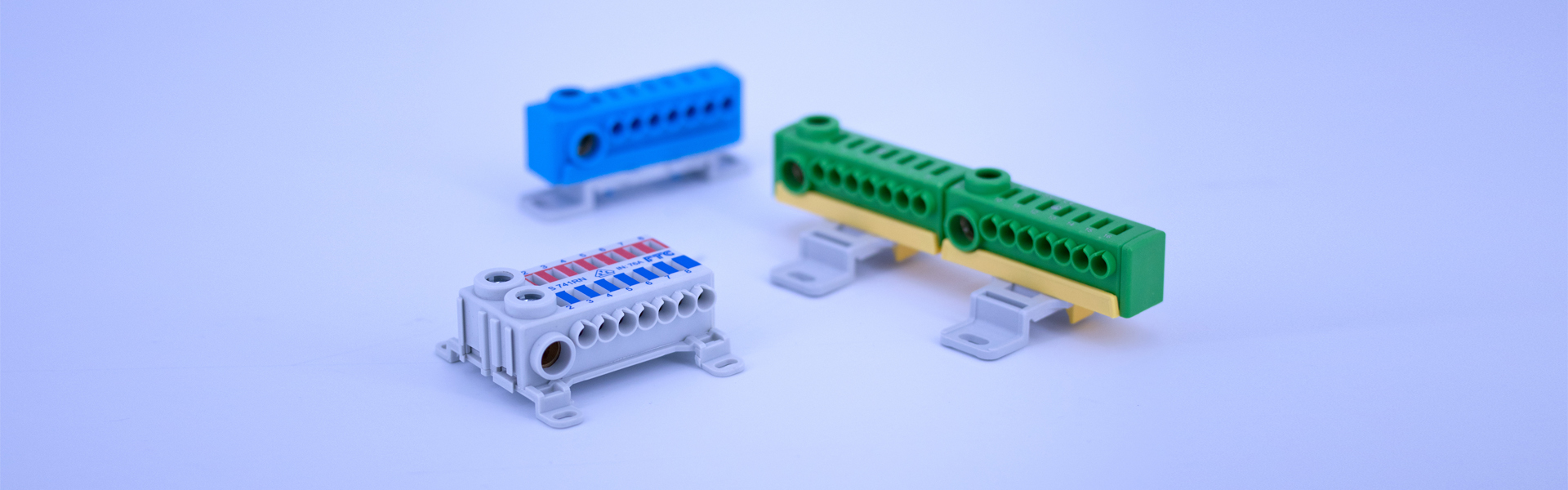

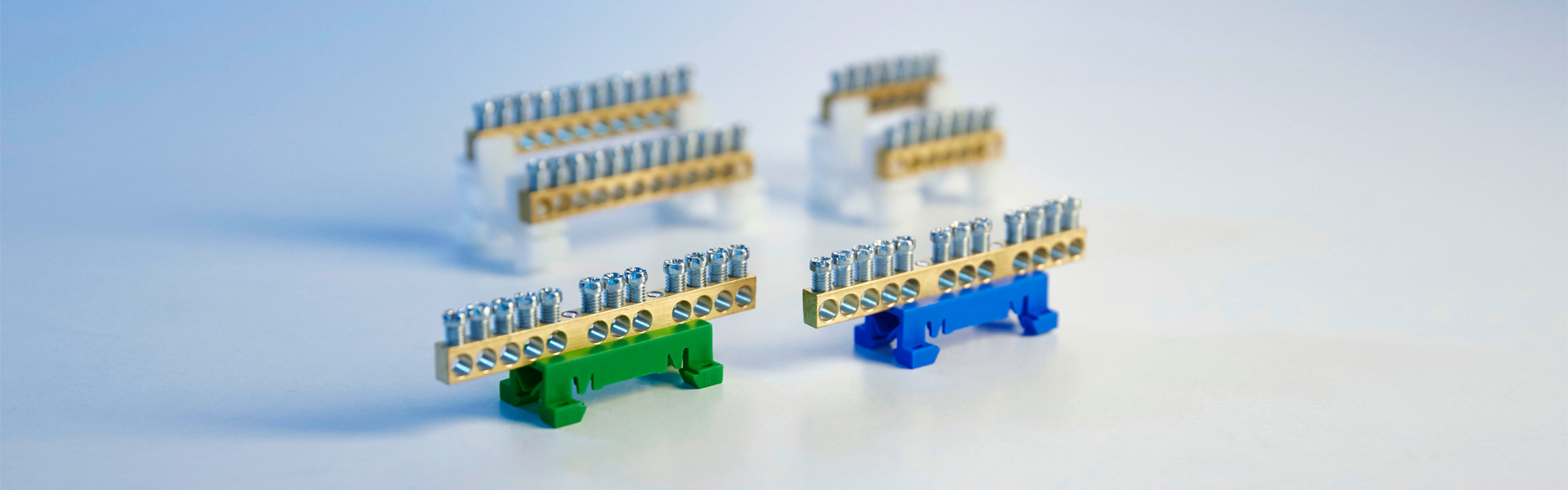

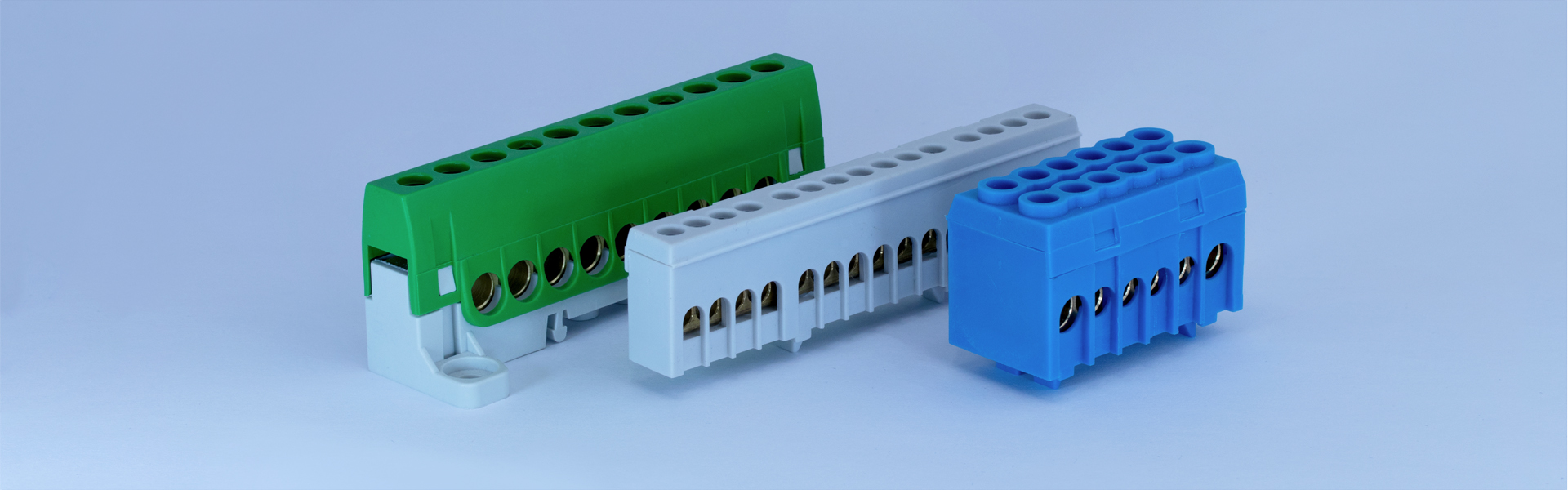

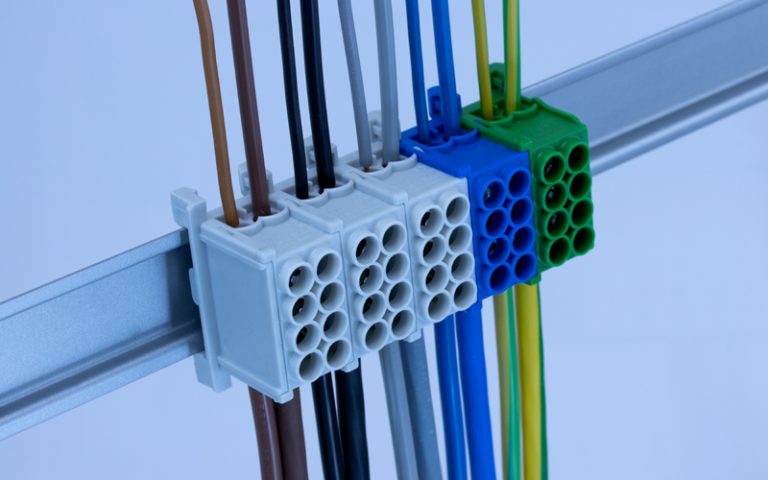

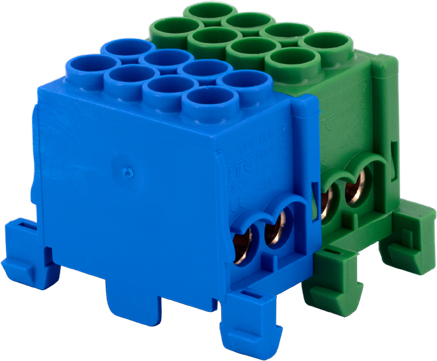

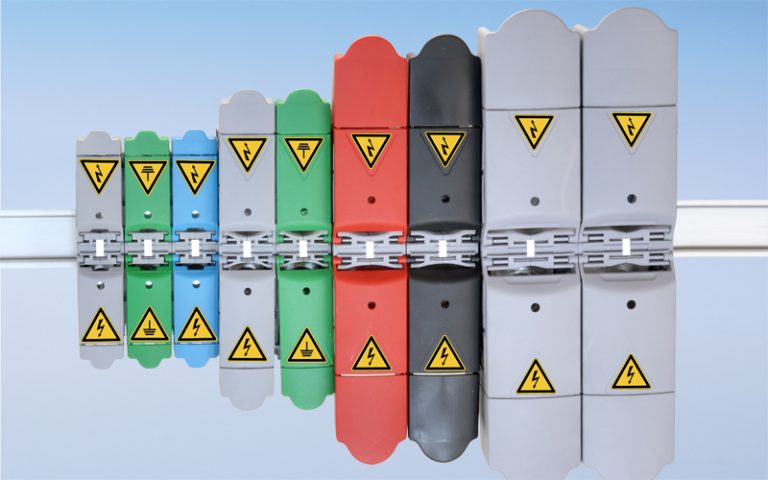

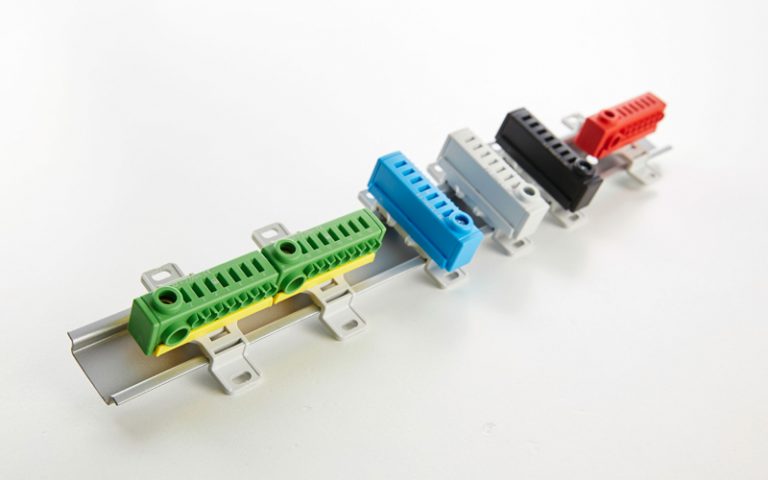

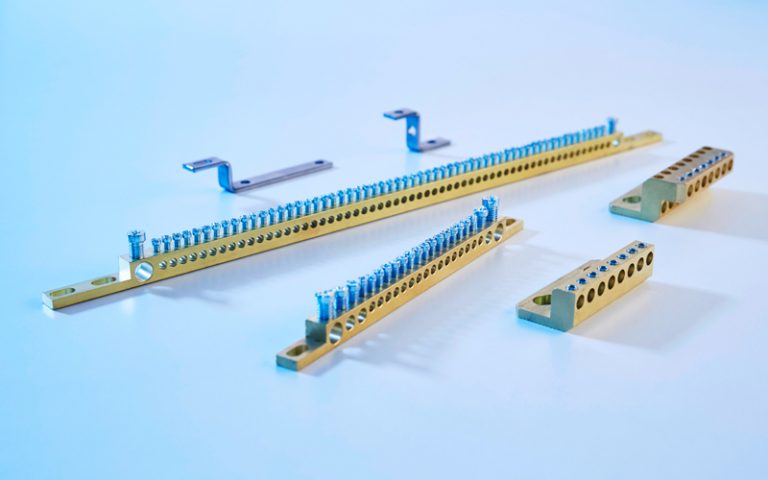

Neutral and Earthing Terminals

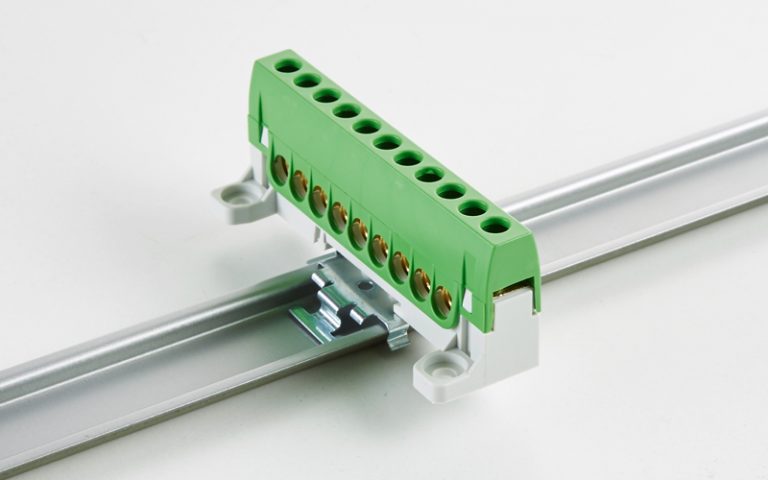

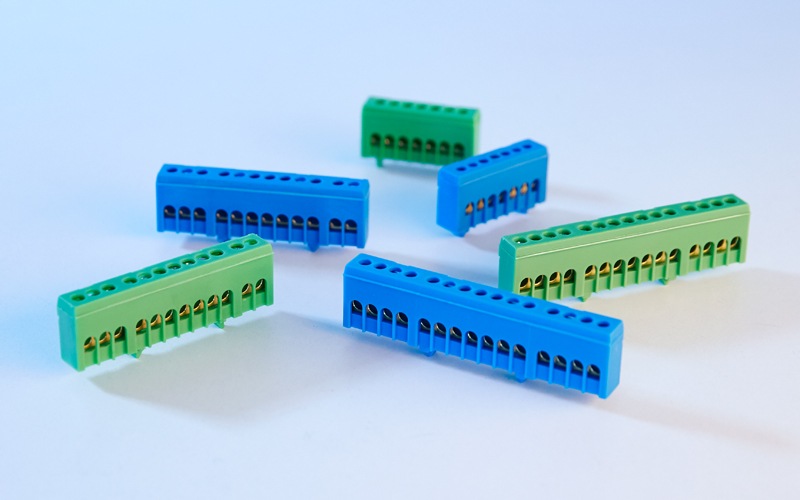

870x-xxFS

Strongly positioned and highly flexible. FTG has a strong portfolio for neutral and earthing terminals, especially for finger-safe systems that are mounted on DIN mounting rails. - 7, 12 or 15 connections - Colors: green, blue, gray - max. 63 A - Connection cross-sections: 870x-xxFS = 1.5 - 16 mm² 870x8-4FS = 1.5 - 25 mm²

870GFS9xx and 870GFS9Mxx

Finger-safe neutral and earthing terminals for mounting on the base plate (870GFS9xx) as well as on the DIN mounting rail (with steel spring holder - 870GFS9Mxx). The connection module 870GFS-VB is available for stringing several terminals together. - 9 connections - Colors: green, blue, gray, black, red - max. 160 A - IP 20 - Connection cross-sections 9 x ø7.5 mm

DIN rail holder NPET

Maximum flexibility is achieved with the DIN rail support NPET. The module allows the construction of an individual system with brass clamping bars or busbars in combination with bow terminals of FTG.

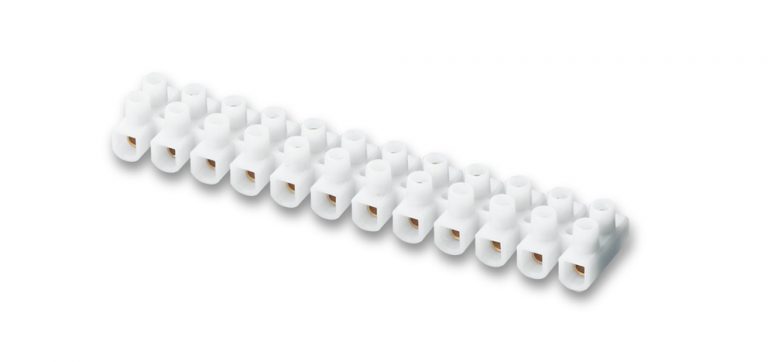

Terminal stripes

– Colors: natural, black

– Heat resistance up to approx. 80 ° C – 100 ° C (depending on the terminal strip)

– Number of poles: 12

– for conductor cross-sections between 2.5 and 25mm² depending on the version

Terminals / Porcelain Terminals

The porcelain terminals, made of porcelain KER DIN 40985, are glazed and approved according to DIN EN 60998. The terminals, are available in one to three-pole versions for cross-sections between 2.5 mm² and 16 mm².

Depending on the application, the terminals are available with or without a mounting hole and with or without wire protection.

Screwless Terminals

Flat Plugs

The flat connectors are easy to use and can be used flexibly. The assembly is also done quickly, as these are designed for standard 6.3 mm x 0.8 mm flat connectors.