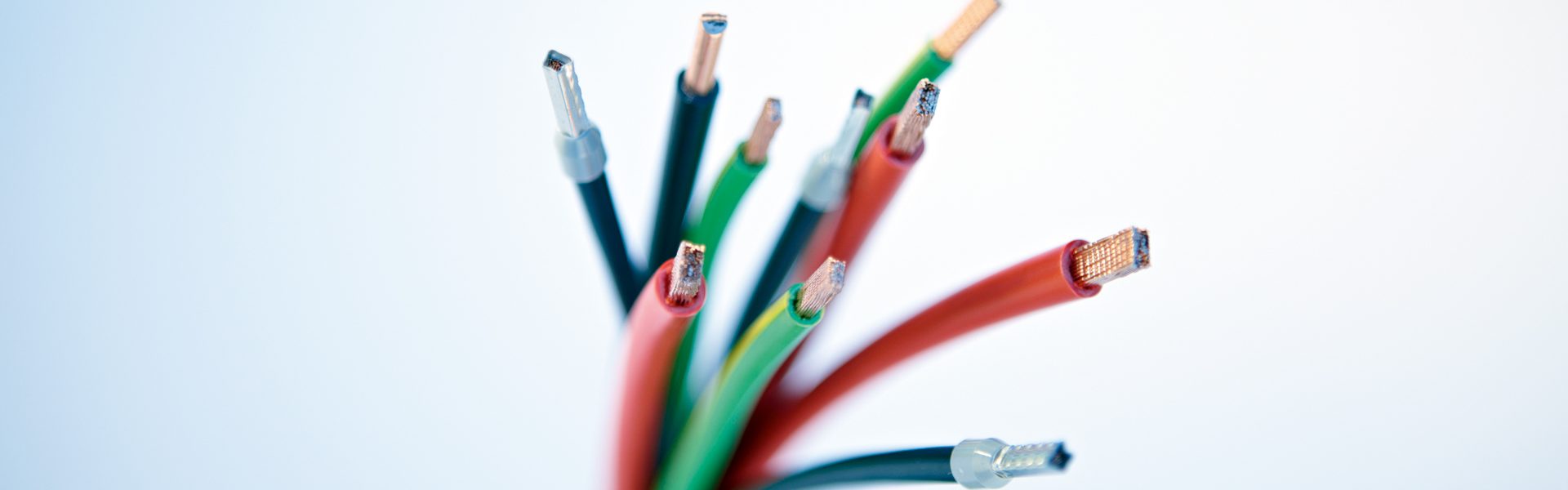

The origin of the power connection – FTG in Triberg has been manufacturing pre-assembled cables for connecting electrical power since 1962. The cable harnesses can be put together individually in lengths, colors and the type of assembly, whether with wire end sleeves, cable lugs or ultrasonically welded.

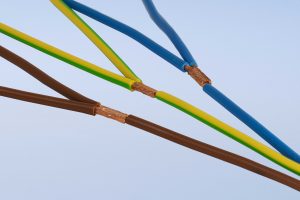

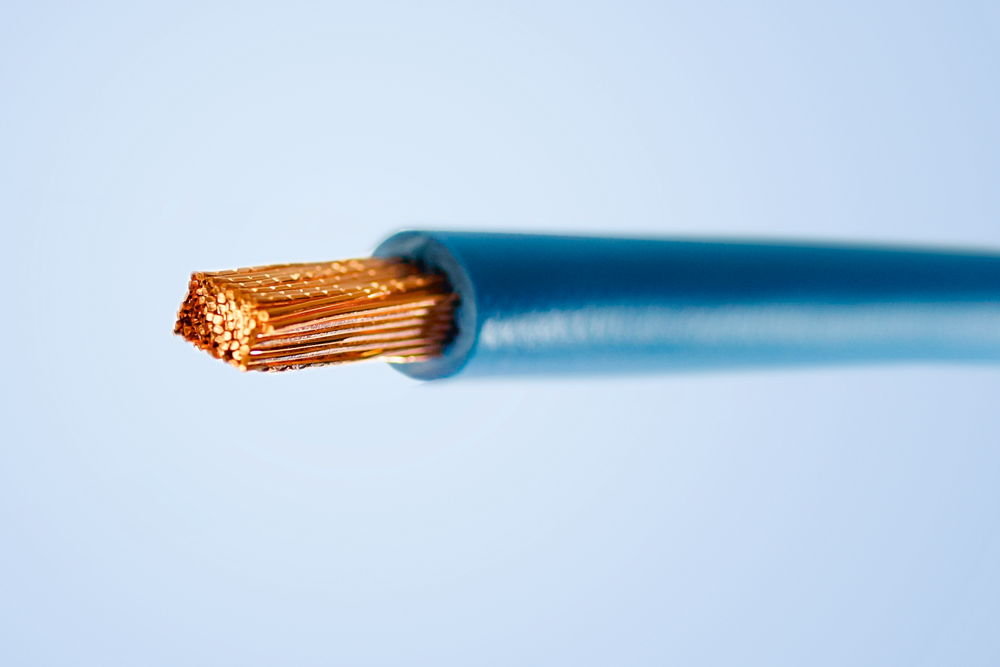

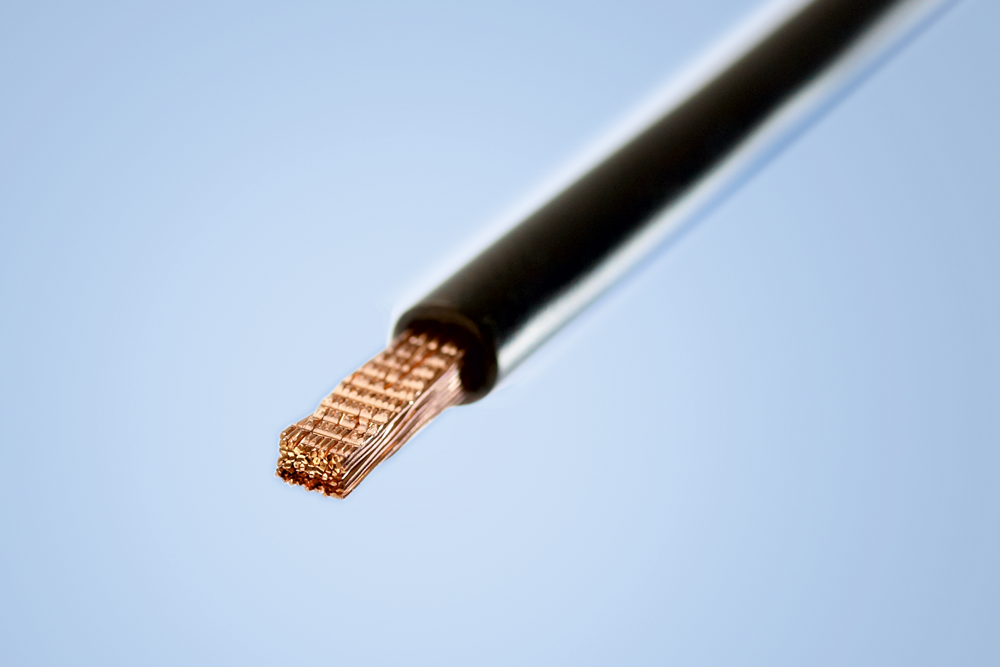

Examples of prefabricated Cable of FTG

Techniques of premanufactured cabels

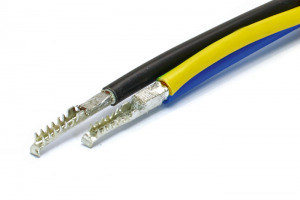

Ultrasonically welded

Advantages of ultrasonically welded cables ends:

+ welding makes wires more compact

+ many cables with different cross-sections up to 80 mm² (only bare copper conductors)

+ a visual inspection of the cable assembly can be carried out quickly

+ wrongly crimped, leads to a transmission resistance and triggers a heat and fire hazard, which can consequently end in fire. This danger nearly does not exist with ultrasonically compressed cable ends!

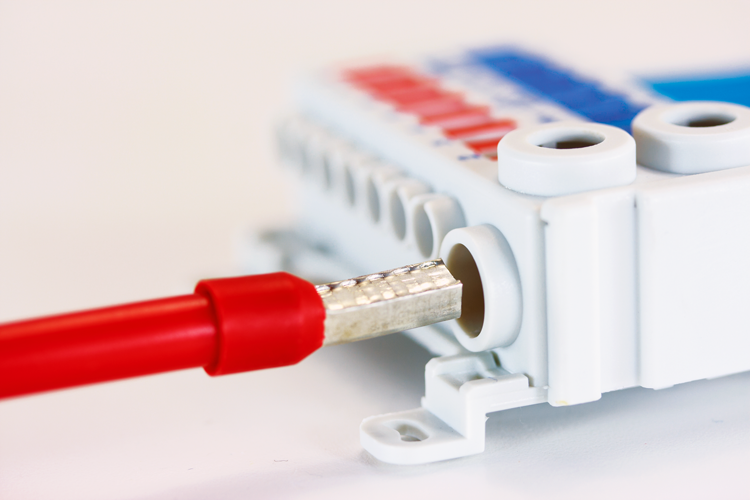

Crimping

Advantages of crimped cable ends:

+ large selection of accessories (ferrule, ring cable lug, fork lug, etc.)

+ up to 120 mm² cable cross-section

Please note:

– Crimping is now an older standard compared to today’s ultrasonic welding.

– In addition, additional accessories mean a further work step, which entails additional costs for the customer, but sometimes corresponds to the necessity.

Application area of ultrasonically welding

- - Switch board building

- - Domestic installations with short cable bridges

- - Vehicles

Application area of Crimping

Wherever a cable connection is required or individually assembled cable harnesses with different connections is required.

Cable product lines

Flexible Cabel bridges

Flexible cable bridges from FTG in single or multi-wire versions from different cross sections and colors.

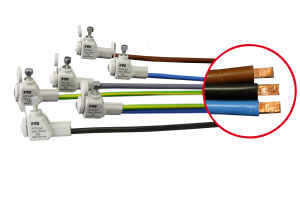

Equipment of PLC connectors

For PLC controls, FTG also equips the plugs with cable harnesses according to individual specifications.

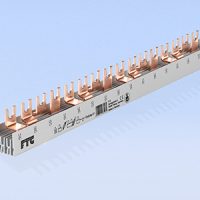

Row Connectors

For space-saving connection of safety devices to the next DIN mounting rail row, rigid and flexible row connectors are available, which run in one to four-pole variants on the side or behind the DIN rail system.

Inquire about individual cable bundles

Product Range of FTG

CONTACT

Friedrich Göhringer Elektrotechnik GmbH

Gerwigstrasse 8

78098 Triberg, Germany

Phone +49 (0) 7722-9636-0

E-Mail info@ftg-germany.de