Busbars of FTG

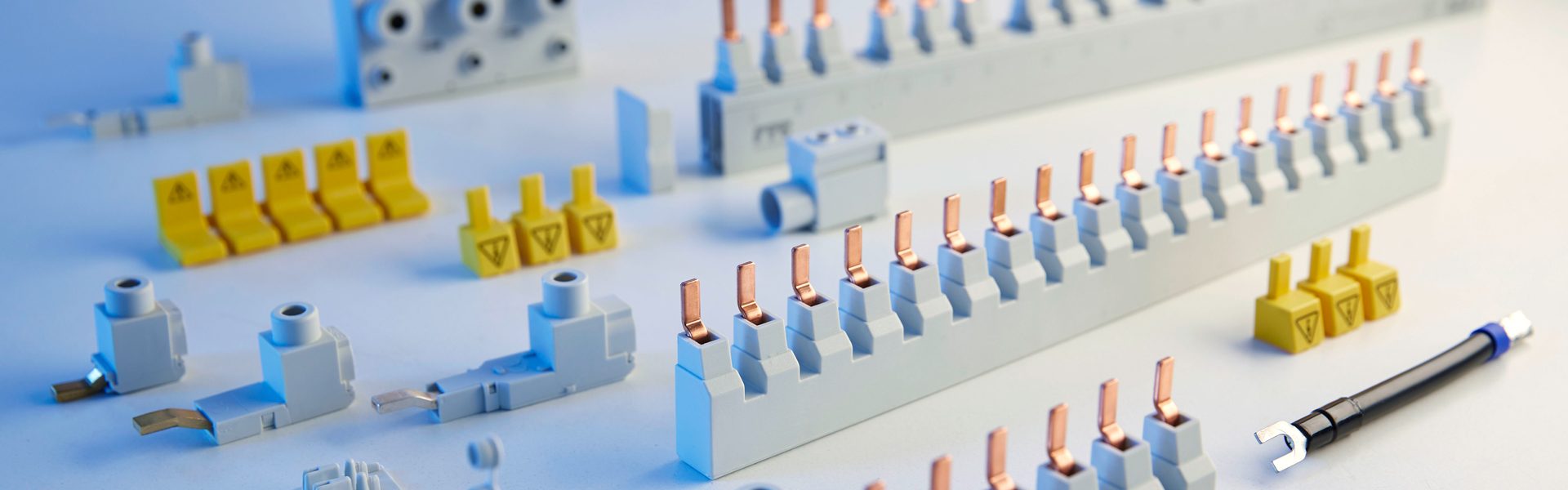

Flexibility, Reliability and Safety for UL applications. Numerous applications can be covered, there are no restrictions due to the assembly situation. Regardless of whether feed from above, from below, from the middle or from the side – the FTG busbars fit all requirements. There is an extensive range of accessories for the “made in Germany” busbars, such as connection terminals or contact protection caps.

FTG-Phasenschienen für Anwendungen nach UL508 / 1077

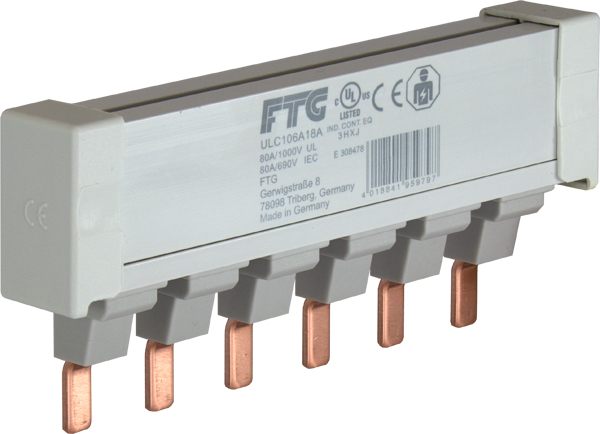

Busbars for circuit breakers according to UL508 / 1077 can also be used in conjunction with fuse holders according to UL512 and auxiliary switches. These are available in versions with 1, 2 and 3 phases and are designed for 80 or 100 A (with central feed 160 or 200 A). Some busbars can be sawed, and finger safety is ensured by end caps. The accessories include connection terminals and contact protection caps. In principle, the busbars according to UL508 are also suitable for DC applications.

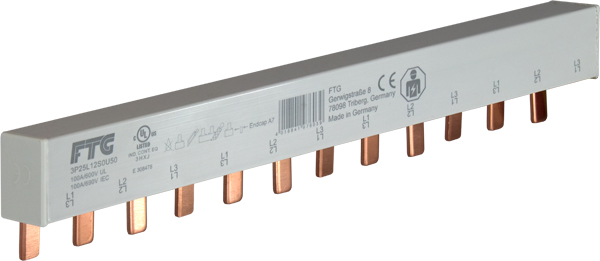

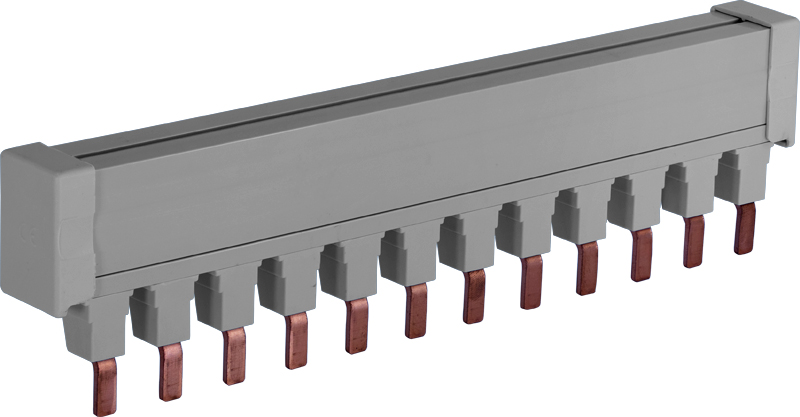

Busbars for circuit breakers UL489

The one to three pole busbars for circuit breakers UL489 are designed for a load of up to 115 A with a busbar cross-section of 16 sqmm. The system can be further connected, for which there are suitable accessories such as connection terminals and contact protection caps. The UL489 busbars cannot be sawn, but are already made to the desired length.

First cuttable busbars for circuit breakers UL489

The ULcut busbar is the first sawable UL489 rail that is offered by the meter. You can choose between a wide standard range of step spacings, cross-sections, etc. If necessary, the busbars can be extended and offer finger-safe protection IP20. The protected technology is ideal for use in areas with a high degree of pollution, as it is a completely closed system. The end cap A68, plugged in, is also available as an option for the matching power supply terminals.

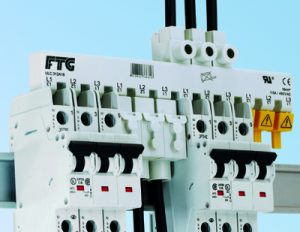

UL Busbars in application

UL508

UL489

ULcut [sawable UL489 busbar]

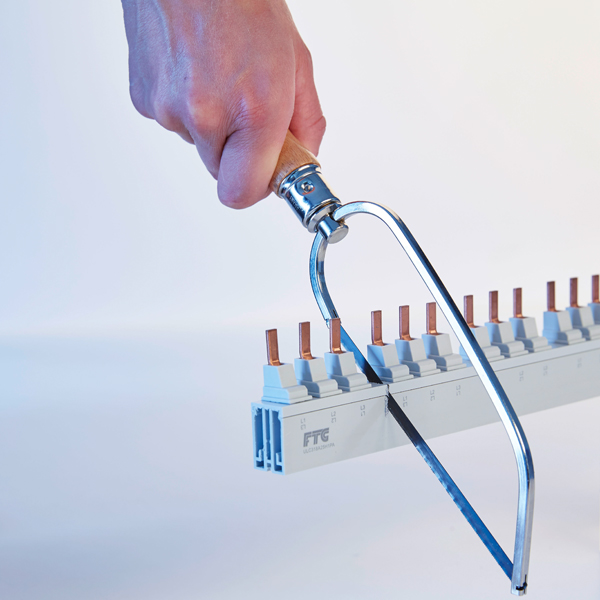

Sawing a ULcut busbar of FTG

1. Saw busbar

The ULcut busbar can be sawn and shortened to any length by the meter.

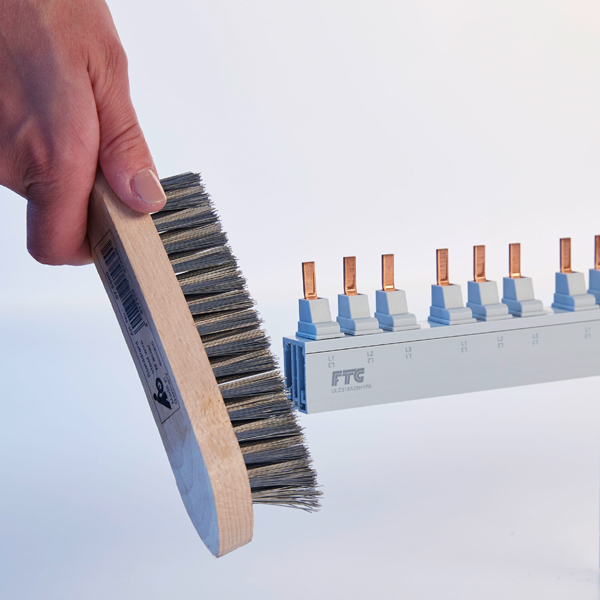

2. Clean the busbar

After the busbar has been shortened to the required length, the ends must be cleaned with a wire brush.

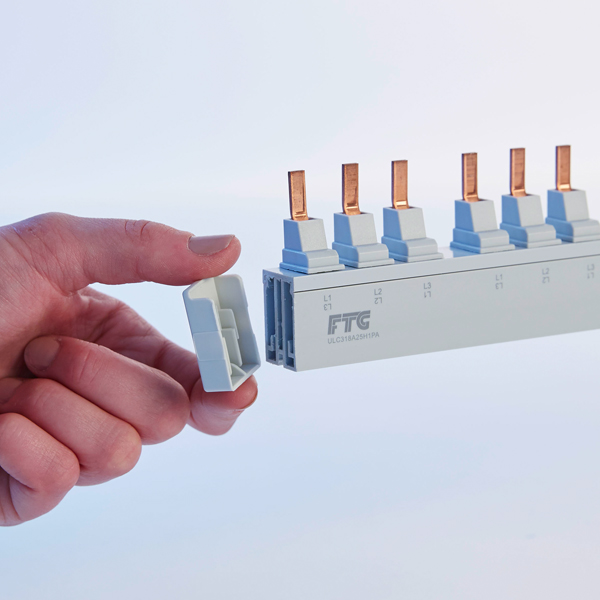

3. Cover busbar ends with end caps

To ensure finger safety, the busbars must be provided with end caps.

4. Attach busbar and feed-in terminal

The UL busbar can now be attached to the UL489 circuit breaker in combination with the connection terminal.

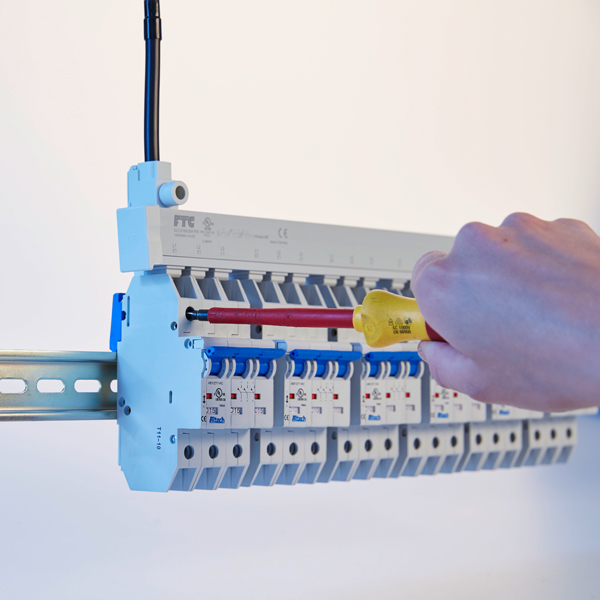

5. Fix busbar by screwing

Now the busbar is fixed to the circuit breaker so that the busbar is firmly connected.

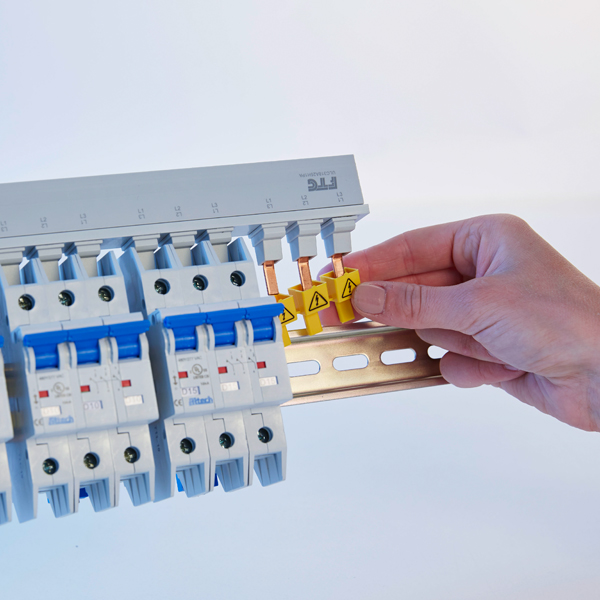

6. Attach contact protection caps

If connection lugs are provided on the busbar for later additions, these must be provided with contact guards.

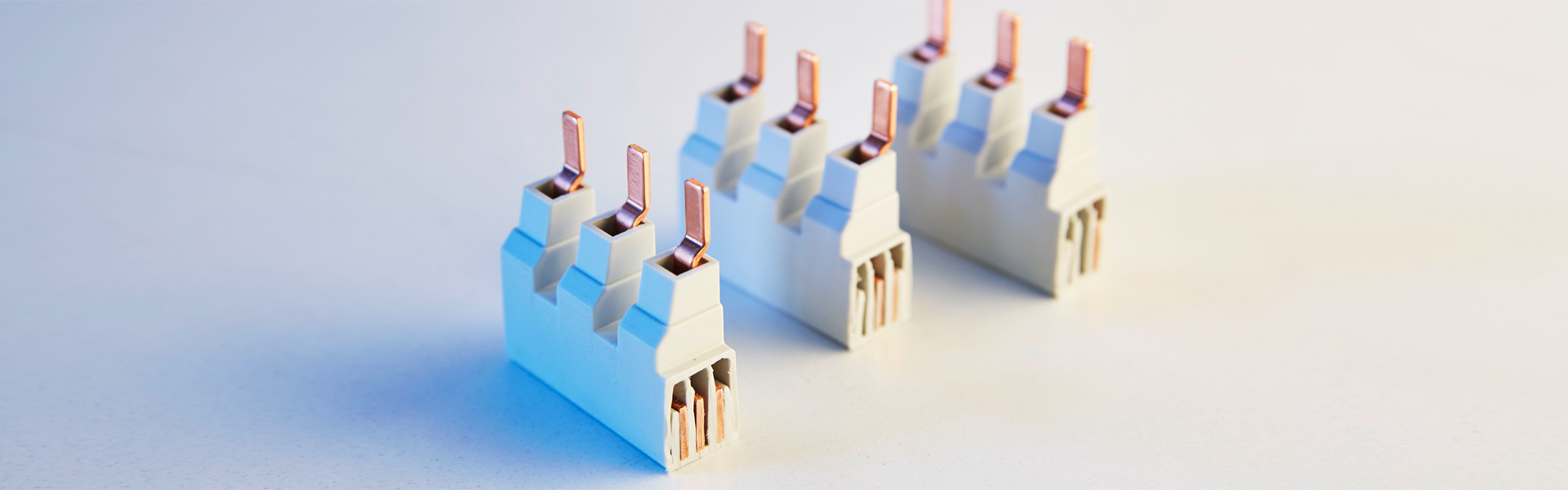

UL Accesories

Feed-in Terminals

FTG offers for each UL busbar the suitable connection / feed-in terminal in different cross sections.

Contact protection cover and end caps

Contact protection is available for unused connection lugs and suitable end caps for cut goods by the meter.

Get a quote for your individual UL busbar

Product range of FTG