Quality

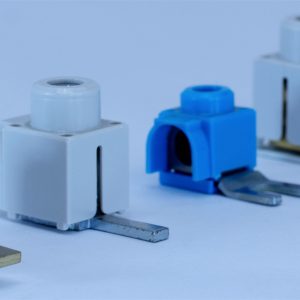

Product development

A product’s high quality is always based upon its development. At the FTG development department in Triberg, each and every year a staff of 6 come up with a number of new products or adapt existing products to new requirements. Thanks to state-of-the-art 3D design and in-house prototype production, the company’s own test laboratory can thoroughly check all products before the start of production. This pre-SOP inspection guarantees an economically efficient development, lest, for example, expensive moulding tools have to be produced.

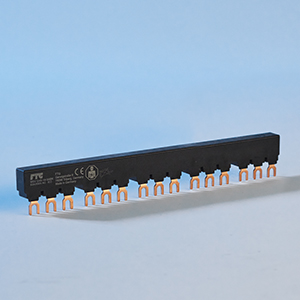

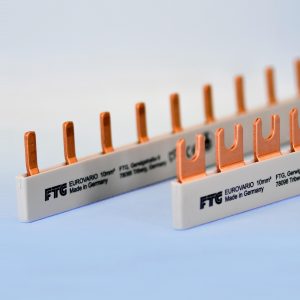

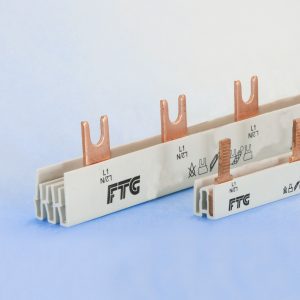

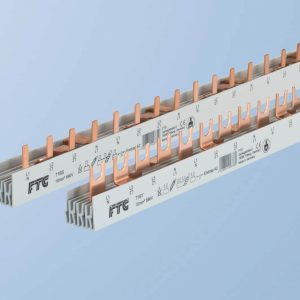

Production

FTG production is always state-of-the-art. Modern machines and plants complement a tried-and-tested technology. FTG puts much emphasis on every single member of staff’s duty of care for the products.

ISO certification

FTG’s most important departments have been DIN EN ISO 9001:2015-certified. FTG doesn’t deem a certification a mere formality, but rather sees the improvement potential provided by the certification proper and also the annual audits. On average, one department p.a. is certified.

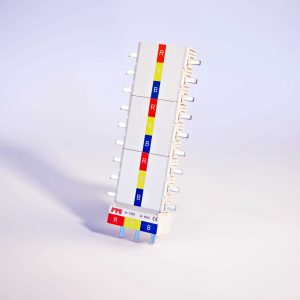

Certification of the FTG products

It goes without saying that FTG also certifies its own products in accordance with international standards. Depending upon their field of application, the products are certified by FTG pursuant to, say, UL, CSA or VDE. Continuous audits again and again confirm FTG products’ high quality.

Test laboratory

FTG products can be subjected to a number of tests in FTG’s own test laboratory. These tests currently comprise:

- Thermal tests

- Tensile force tests

- High voltage tests, AC and DC

- Pulse tests

Documentation

There is extensive documentation material for the FTG products, describing an article’s important parameters. A wide range of brochures and information sheets aside, FTG provides data sheets for every product that proof important technical data. A number of products are delivered with product inserts and assembly instructions to ensure the availability of important data and a proper, smooth and, above all, fast assembly.

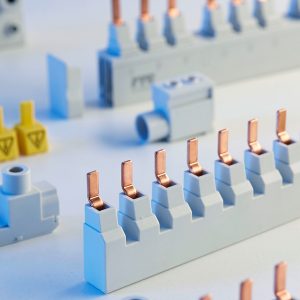

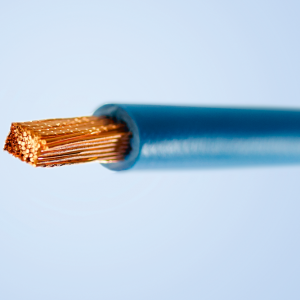

Materials

FTG only processes materials that meet European standards. Be it the metals used, like copper or brass, or the plastic parts used for insulation – FTG products always conform with

- CE

- RoHS

- REACh

- Insulations in part free of halogen

Environment

Recycling these days is a matter of course and still shows astonishing results. The production process hardly yields any waste that wouldn’t be recycled. All metal waste is recycled, of course, and plastic waste is also (re-)granulated. The company’s electricity is generated in its own combined heat and power station.